Advantages and Disadvantages of Woodruff key?

What is a Woodruff key?

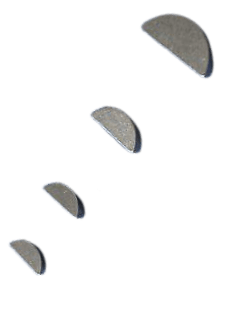

A Woodruff key is a half-moon-shaped machine key that prevents gears, hubs, or other parts from slipping out of place. In this answer, Hubs will be substituted for another type of part.

Woodruff Key

Advantages of Woodruff keys:

- Eliminates slippage between machine components thereby preventing wear and the subsequent need to replace parts.

- More useful for high-speed rotation assemblies.

- Preventing the slippages decreases the breakage/damage on expensive pieces.

- It can be adjusted easily.

- The loss of power transfers is less.

Disadvantages of Woodruff keys:

- There are sometimes forces to put pressure on the woodruff key as the machine runs such as changing gear teeth contact, wearing of rotor surfaces, etc. When these forces acting upon the Woodruff Key exceed those which it’s designed to withstand by its weight or inertia, failure becomes inevitable and can result in significant destruction.

- The disadvantage is they can become worn over time due to their constant use.

- The strength of the shaft gets decreased due to the depth of keyways.

- Woodruff keys also need special tools for removal so once they are applied this can be an additional cost.

- A woodruff key jams into its seat when pressure is applied from behind it on its concave end, while the convex end provides an outward wedging force for holding against rotation.

- Most locks use either flat keys or tubular keys so they can fit inside lock cores using many different angles and configurations, but woodruff keys have limited applications.

- If a new production process calls for a different size or shape key, the component may need to be reworked to accommodate it.

- It blocks the axial motion of a shaft that is connected to the pulley’s hub bearing.