What is Throttling Process?

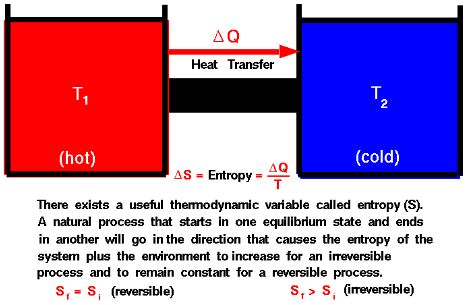

In thermodynamics, throttling refers to a process where a fluid undergoes a rapid and irreversible expansion through a valve or a throttle. This expansion results in a significant drop in pressure without any significant change in temperature. The throttling process is considered an isenthalpic process, meaning there is no change in enthalpy during the process.

Here are some key characteristics of throttling in thermodynamics:

- Isenthalpic Process:

- As mentioned, throttling is an isenthalpic process, which means the enthalpy of the fluid remains constant during the expansion. Mathematically, it can be expressed as h1 = h2, where h1 is the enthalpy before throttling, and h2 is the enthalpy after throttling.

- Adiabatic Process:

- Throttling is often assumed to be an adiabatic process, meaning there is no heat exchange with the surroundings during the expansion. The assumption is based on the rapid and irreversible nature of the process.

- Nozzle or Valve:

- The throttling process typically occurs through a nozzle or a valve. As the fluid passes through this restriction, its velocity increases, leading to a drop in pressure. The expansion is usually so rapid that there is not enough time for significant heat exchange with the surroundings.

- Temperature Drop:

- While the throttling process results in a significant pressure drop, the temperature of the fluid usually remains relatively constant. This is due to the assumption of adiabatic conditions and the isenthalpic nature of the process.

The throttling process is often utilized in refrigeration and air conditioning systems. For example, it is commonly observed in expansion valves or throttling devices within these systems. Engineers and thermodynamic analysts use the principles of throttling to study and design systems where pressure reduction is needed with minimal temperature change.

Applications of Throttling Process

In thermodynamic applications, the throttling process is often employed in various systems to achieve specific goals, particularly in refrigeration and air conditioning systems. Here are some common examples of throttling processes in thermodynamic applications:

- Expansion Valves in Refrigeration and Air Conditioning:

- Throttling processes are commonly used in expansion valves within refrigeration and air conditioning systems. When high-pressure, high-temperature refrigerant liquid passes through the expansion valve, it undergoes a rapid expansion, resulting in a significant drop in pressure. This cooled and expanded refrigerant then enters the evaporator, where it absorbs heat from the surroundings, facilitating the cooling process.

- Thermal Expansion Devices:

- Throttling processes are also utilized in thermal expansion devices, such as the thermal expansion valve (TXV) in refrigeration systems. The valve regulates the flow of refrigerant into the evaporator coil, causing a pressure drop and facilitating the phase change of the refrigerant from liquid to vapor.

- Steam Turbines:

- In steam power plants, throttling processes occur in steam turbines. High-pressure, high-temperature steam is expanded through nozzles or blades in the turbine, resulting in a drop in pressure and the conversion of thermal energy into mechanical energy to generate electricity.

- Gas Flow Control:

- Throttling processes are used in controlling the flow of gases in industrial processes. For example, in natural gas distribution systems, regulators or control valves can be used to throttle the flow of gas to meet specific pressure requirements.

- Thermal Desalination Processes:

- Throttling is also encountered in certain thermal desalination processes. For instance, in flash distillation, high-pressure seawater is throttled through a valve, causing a rapid drop in pressure and resulting in the formation of steam. This steam is then condensed to produce fresh water.

- Supersonic Nozzles:

- Throttling processes are also present in supersonic nozzles used in propulsion systems. For instance, in rocket engines, high-pressure gases are expanded through a nozzle at high speeds, resulting in thrust.

In all these applications, the throttling process is essential for achieving specific thermodynamic effects, such as pressure reduction, temperature changes, and phase transitions. Engineers and designers carefully consider throttling processes in the design and optimization of thermodynamic systems to ensure efficient and reliable operation.

Advantages of Throttling Process

The throttling process in thermodynamics offers several advantages in various applications, especially in refrigeration and air conditioning systems. Here are some of the advantages associated with the throttling process:

- Pressure Reduction:

- Throttling is primarily used to achieve a rapid and controlled reduction in pressure. In refrigeration and air conditioning systems, this pressure reduction is crucial for creating the conditions necessary for the refrigerant to absorb heat in the evaporator.

- Temperature Drop:

- While pressure drops significantly during throttling, the temperature of the fluid typically remains relatively constant. This characteristic is advantageous in applications where a pressure drop is required without a significant change in temperature. For example, in refrigeration systems, the cooled and expanded refrigerant can efficiently absorb heat from the surroundings.

- Phase Change Facilitation:

- Throttling processes facilitate phase changes in substances, particularly in refrigeration cycles. For example, the expansion of high-pressure liquid refrigerant through an expansion valve leads to a phase change from liquid to vapor, promoting the absorption of heat in the evaporator.

- Energy Transfer:

- Throttling is a mechanism for transferring energy within a thermodynamic system. In steam turbines, for instance, the throttling process in nozzles or blades helps convert high-pressure, high-temperature steam energy into mechanical work, which can then be used to generate electricity.

- Efficient Cooling:

- In refrigeration and air conditioning, the throttling process contributes to the efficient cooling of the working fluid. The expansion of the refrigerant results in a lower temperature, allowing it to absorb heat effectively in the evaporator and produce cooling effects.

- Controlled Flow:

- Throttling devices, such as expansion valves, provide a means to control the flow rate of a fluid in a system. This control is essential for maintaining proper operating conditions and achieving desired performance levels.

- Simplicity and Reliability:

- Throttling devices are often simple in design and operation, which contributes to their reliability. The straightforward nature of the throttling process makes it a practical and effective method for achieving specific thermodynamic effects in various applications.

While the throttling process has its advantages, it’s important to note that it is also associated with certain limitations, such as energy losses and the potential for irreversibility. Engineers carefully consider these factors when designing and optimizing thermodynamic systems to ensure overall efficiency and performance.

Disadvantages of Throttling Process

While the throttling process has its advantages, it also comes with certain disadvantages, particularly in the context of thermodynamics and engineering applications. Here are some of the drawbacks associated with the throttling process:

- Irreversibility: Throttling is an irreversible process, meaning it is difficult or impossible to return the system to its initial state without external intervention. This introduces inefficiencies in the system, as some of the available energy is lost as a result of irreversibility.

- Energy Losses: The rapid expansion of a fluid during throttling can lead to energy losses, particularly in the form of kinetic energy. This can result in a decrease in the overall efficiency of the system.

- Temperature Fluctuations: While throttling causes a drop in pressure, the temperature of the fluid remains relatively constant. However, there can be some temperature fluctuations due to energy losses, and this may affect the performance of certain systems where precise temperature control is critical.

- Limited Cooling Potential: In some cases, the temperature drop achieved through throttling may not be sufficient for certain cooling applications. Additional cooling mechanisms or stages may be required, leading to increased complexity and energy consumption.

- Complex System Design: Throttling devices, such as expansion valves, need to be carefully designed to ensure proper functioning and efficiency. Achieving optimal performance may require sophisticated engineering solutions.

- Noise Generation: Throttling processes can generate noise, especially when high-pressure fluids are rapidly expanded through valves or nozzles. This can be a concern in applications where noise levels need to be minimized.

- Maintenance Challenges: Throttling devices may experience wear and tear over time, leading to maintenance challenges. The moving parts in valves or nozzles may require periodic inspection and replacement.

- Risk of Cavitation: In certain applications, such as in pumps or nozzles, rapid pressure drops during throttling can lead to cavitation. Cavitation occurs when the local pressure drops below the vapor pressure of the fluid, causing the formation of vapor bubbles, which can collapse with damaging effects.

It’s important for engineers and designers to carefully consider these disadvantages when incorporating throttling processes into thermodynamic systems. Depending on the specific requirements and constraints of a given application, alternative processes or supplementary components may be considered to mitigate these drawbacks.

Examples of Throttling Process

Throttling processes are commonly encountered in various applications across different fields, particularly in thermodynamics, fluid dynamics, and control systems. Here are some examples of throttling processes:

- Refrigeration and Air Conditioning Systems:

- Throttling occurs in expansion valves within refrigeration and air conditioning systems. High-pressure liquid refrigerant passes through the expansion valve, undergoes rapid expansion, and experiences a significant pressure drop. This process is crucial for creating the conditions necessary for heat absorption in the evaporator, leading to cooling effects.

- Steam Turbines:

- Throttling is used in steam turbines, where high-pressure, high-temperature steam is expanded through nozzles or blades. This leads to a drop in pressure, facilitating the conversion of thermal energy into mechanical work to generate electricity.

- Gas Flow Control:

- Throttling processes are applied in controlling the flow of gases in industrial processes. Control valves or regulators are used to throttle the flow, ensuring that the gas is delivered at the desired pressure.

- Rocket Engines:

- In rocket engines, throttling occurs when high-pressure gases are expanded through a nozzle at high speeds. This process generates thrust and propels the rocket.

- Supersonic Nozzles:

- Throttling is present in supersonic nozzles used in propulsion systems, such as in jet engines. The rapid expansion of high-pressure gases through the nozzle results in increased velocity and thrust.

- Hydraulic Systems:

- Throttling processes are employed in hydraulic systems where control valves regulate the flow of hydraulic fluid to control the speed and force of actuators.

- Natural Gas Distribution:

- Throttling devices, such as regulators, are used in natural gas distribution systems to control the flow of gas and maintain a consistent pressure in the pipelines.

- Thermal Desalination Processes:

- Throttling is encountered in certain thermal desalination processes. For instance, in flash distillation, high-pressure seawater is throttled through a valve, leading to a pressure drop and the formation of steam, which is then condensed to produce fresh water.

- Liquid Rocket Propulsion:

- Throttling is employed in liquid rocket engines to control the flow rate of propellants, allowing for adjustments in thrust and velocity.

These examples highlight the diverse range of applications where throttling processes play a crucial role in achieving specific thermodynamic effects, pressure reductions, and controlled fluid flow.

Frequently Asked Questions – FAQ’s

What role does throttling play in the efficiency of refrigeration systems?

Throttling is essential for achieving efficient cooling in refrigeration systems by creating the necessary temperature and pressure conditions for the refrigerant to absorb heat effectively in the evaporator.

In what industrial applications is throttling commonly used for gas flow control?

Throttling is frequently employed in industrial applications to control the flow of gases, ensuring precise pressure regulation in processes such as manufacturing and chemical production.

How does throttling contribute to the operation of steam turbines?

Throttling occurs in steam turbines as high-pressure steam expands through nozzles or blades, leading to a pressure drop and the conversion of thermal energy into mechanical work for electricity generation.

Are there any disadvantages associated with the throttling process?

Yes, some disadvantages include irreversibility, energy losses, and potential temperature fluctuations. Engineers need to carefully consider these drawbacks in system design.

Can you provide an example of throttling in everyday life?

An example of throttling is the expansion of liquid refrigerant through an expansion valve in a household refrigerator, leading to a pressure drop and cooling effects in the evaporator.

Why is throttling considered an isenthalpic process?

Throttling is considered isenthalpic because there is no exchange of heat during the process, and the enthalpy of the fluid remains constant.

What is the primary purpose of throttling in refrigeration systems?

Throttling in refrigeration systems is used to create a low-pressure, low-temperature environment in the evaporator, allowing the refrigerant to absorb heat efficiently and produce cooling effects.

What is the significance of pressure reduction in throttling?

Pressure reduction in throttling is crucial for creating the necessary conditions for phase changes and efficient heat absorption, making it a fundamental aspect of various thermodynamic processes.

How does throttling contribute to energy transfer in a thermodynamic system?

Throttling facilitates the conversion of high-pressure fluid energy into other forms, such as mechanical work in steam turbines or cooling effects in refrigeration systems.

What is the throttling process in thermodynamics?

Throttling is a rapid and irreversible expansion of a fluid through a valve or nozzle, resulting in a significant pressure drop without a substantial change in temperature. It’s often employed in refrigeration, air conditioning, and other thermodynamic applications.