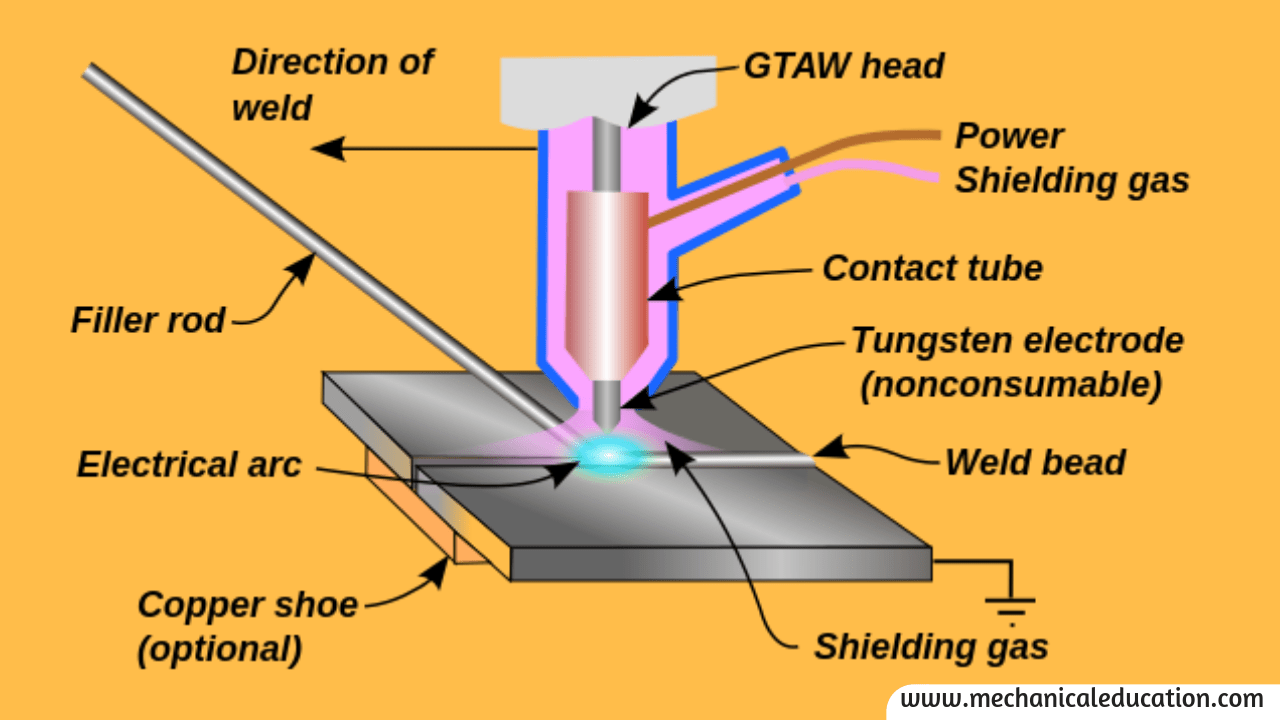

Tungsten Inert Gas Welding process:

- TIG (Tungsten Inert Gas) Welding is used for high-quality requirement. In this gas welding electrode is non-consumable tungsten. the welding metal thickness should be about 5 mm.

- Inert gas welding has less efficiency and a slow process.

- This process is done by producing the arc between the non-consumable tungsten and welded metal. to shield the electrode and weld pool the gas should be fed through the torch.

- We can use different types of shielding gases in this welding process like.

- Argon, Argon+Hydrogen, Argon+Helium.

- To increases, the heat input helium is added. and to get clean result welds and high heat input Hydrogen is added.

Applications of TIG welding:

- Tungsten Inert Gas is used for welding sheet metals.

- This is used for welding high temperature and hard surfacing materials.

- This method is also used for stainless steel, magnesium alloys, copper base alloys etc.

- This is also used for Aircraft industry applications.

- This welding is used in the fabrication of rocket motors.

Advantages of Tig welding:

- This welding process is highly used for thin materials. this type of welding gives good results for thin materials.

- In this welding, there is a clear visibility of arc and workpiece, due to this, it can operate easily.

- In this there is no flux coating due to this there is no harm by flux entrapment.

- The work can don easily at any position, clean and perfectly by less spatter.

Limitations of TIG welding:

- Due to the requirement of additional filler rod, it is relatively a slow process.

- Tungsten material contaminates the weld, which is hard and brittle.

- Shield causes Contamination to the weld metal when the filling comes out from the inert gas.

- Equipment cost is high.

Please Subscribe! and Don’t forget to Follow us on Facebook, Twitter, Linkedin, Instagram and Google Plus.