Torque Converter – Working Principle, Construction & Parts of Torque converter

What is a Torque Converter?

A torque converter is a power transmission device by using the only fluid as a medium. torque converter transmits the power through fluid couplings and it does not contain any connecting gears in it, it is just a fluid connecting device to transmit the power with high torque.

Working principle of Torque Converter:

When the engine gets started impeller in it rotates with high speed, by this rotational speed fluid passing out from the impeller increases to high velocity and stricks the turbine blades, this makes the turbine shaft to rotate. to increase the torque output we use stator and to transfer this rotating power clutch is replaced which can engage and disengage when we required a rotational moment and there is a coupling in the transmission which is a fluid coupling called as a fluid flywheel.

Construction of Torque Converter:

A torque converter consists of two half doughnut-shaped shells, this is presented with the interior fins. It has two open ends with both the units are faced very close to each other and faced on the same sides with each other. This forms the shell shape without contacting. In this, the interior shell is filled with the oil.

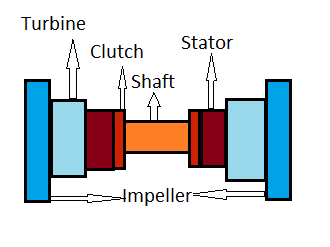

Parts of a Torque converter:

The following are the parts of Torque Converter:

- Turbine

- Impeller

- Stator

- Clutch

Turbine:

Turbine is an important element in this device to make the shaft to rotate with the help of high-velocity fluid.

Impeller:

This makes the fluid to flow with high velocity and makes the turbine to rotate.

Stator:

it plays an important role in increasing the output torque.

Clutch:

This is used to transfer the rotational movement whenever required.