What is a Turbine:

A Turbine is a rotary mechanical device the energy gets from fluid flow and converts it into useful work. Turbines are used in thermal energy generation, jet engines, large machines, space shuttle engines etc.

The work produced by the turbine can be used for generating the electric power when combined with a producing thrust this is in the case of the jet engine. Turbine is a turbo machine with at least one moving part called a rotor assembly, which is a shaft with blades attached. In this high-pressure turbine is a multi-layer structure that used to convert steam to shaft power.

This has more efficient but it requires a lot of steam to start the turbine. HP Turbine is usually a double flow turbine which has an impulse control stage followed by reaction balding at each end of the element. Hp turbine has 10 stages in it. It used to produce around 40% of the gross power output of the power plant. It has 3 to 4 Regulating extraction lines. which is used to provide steam for the different type of uses like Decelerator, high-pressure feed-water heaters, and feed-water pumps.

STEAM TURBINE:

A Steam Turbine is a machine for generating mechanical power in rotary motion from the temperature of steam at temperature and pressure above that of an available skin.

This is the most widely used and most powerful turbine are those driven by steam. In modern turbine technology includes nuclear steam plant as well as the production of steam supplies from other sources.

Different types of turbines:

1) Impulse Turbine.

2) Reaction Turbine.

IMPULSE TURBINE:

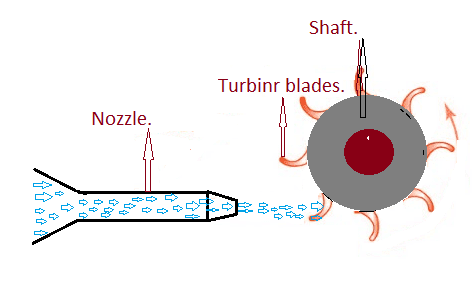

This turbine works on the principle of impulse, The flow of steam through the nozzle and the moving blade of the turbine take place in that case the steam is expanded only in nozzle and pressure at outlet sides of blades is equal to the inlet side. In this, the pressure drop takes place only in a nozzle and not happens in moving blades due to the blade passage of constant cross-section area. the chances of flow separation are greater which results in lower stage efficiency due to the rotor blade passages do not cause any acceleration of fluid.

REACTION TURBINE:

In this type of turbine, the pressure drops at the nozzles and at the moving blades. When the steam passes through the moving blades the pressure drop suffered and causes a further generation of kinetic energy within the one moving blades, Giving rise to the reaction and adds to the propelling force which is applied to the rotor to the turbine shaft.

This turbine works on the principle of impulse and reaction turbine. In this energy, transformation occurs in fixed and moving blades. the higher stage efficiency occurred due to the separation of flow is less. In this, the energy transfer and transformation is caused due to the rotor blades.

This also depends on the type of Flow directions and Heat supply:

Direction:

Axial flow turbine: In this, the steam flows in the direction of axial of the shaft. this is more useful to large Turbo-generators and mostly used in modern steam power plants.

Radial flow turbine: In this, the direction of flow is radial, in this, it has a separate generator at the end to end shafts.

Tangential flow turbine: In this, the direction of steam flows in tangential. This is not as much as an efficient machine at sometimes it is used for driving power station auxiliaries.

Heat supply:

Single Pressure turbine:

- In this turbine, the source of steam supply is single.

Mixed pressure turbine:

- This used to supply at the different pressure in two sources. this is used in the nuclear power station where both sources are used continuously.

- This is used in many industries.

Reheated Turbine:

- This is used to expand with higher temperature return to the boiler, during the passage through the turbine steam may be taken out to be reheated in the reheated incorporated in the boiler.

- This is used to improve the power output and efficiency and also to avoid erosion and corrosion in balding.

Please Subscribe! and Don’t forget to Follow us on Facebook, Twitter, Linkedin, Instagram and Google Plus.