What is Simple Vapour Compression Refrigeration systems?

A Simple Vapor Compression Refrigeration (VCR) System is a common and efficient method used for cooling in various applications, such as air conditioning, refrigeration, and heat pumps. The basic working principle involves the circulation of a refrigerant through a closed loop, undergoing phase changes to absorb heat from one area and release it in another. Here’s a breakdown of the main components and their functions in a simple vapor compression refrigeration system.

Main components & Functions of a simple vapor compression refrigeration system

- Compressor:

- The compressor is the heart of the vapor compression system.

- It takes low-pressure, low-temperature vapor refrigerant from the evaporator and compresses it to high-pressure, high-temperature vapor.

- The work done by the compressor increases the internal energy and temperature of the refrigerant.

- Condenser:

- The high-pressure, high-temperature vapor from the compressor enters the condenser.

- In the condenser, heat is released to the surroundings, and the refrigerant undergoes a phase change from vapor to liquid.

- The condenser is usually a coil or a set of coils with fins to enhance heat exchange.

- Expansion Valve:

- The high-pressure liquid refrigerant from the condenser passes through the expansion valve, which reduces its pressure and temperature.

- This expansion causes the refrigerant to become a mixture of liquid and vapor, with a significant drop in temperature.

- Evaporator:

- The low-pressure, low-temperature refrigerant enters the evaporator.

- Heat from the surrounding space or substance to be cooled is absorbed by the refrigerant, causing it to evaporate and turn into a low-pressure vapor.

- The evaporator is usually a coil or set of coils located in the area to be cooled.

The cycle then repeats:

- The low-pressure vapor from the evaporator is drawn into the compressor.

- The compressor increases the pressure and temperature of the vapor.

- The high-pressure vapor is then condensed in the condenser, releasing heat to the surroundings.

- The high-pressure liquid refrigerant passes through the expansion valve, where it undergoes a pressure drop, leading to a mixture of liquid and vapor.

- The low-pressure mixture enters the evaporator, where it absorbs heat and evaporates again.

This continuous cycle allows the system to transfer heat from the space or substance being cooled to the surroundings, providing cooling effects. The refrigerant circulates through the system, changing its state from vapor to liquid and back again, absorbing and releasing heat in the process.

Types of Simple Vapour Compression Refrigeration systems

While the basic components of vapor compression refrigeration systems remain the same, variations in system configurations and applications have led to different types of simple vapor compression refrigeration systems. Here are some common types:

- Single-Stage Vapor Compression System:

- This is the most basic type of vapor compression refrigeration system.

- It consists of a single compressor, condenser, expansion valve, and evaporator.

- Suitable for small-scale applications like household refrigerators and air conditioners.

- Two-Stage Vapor Compression System:

- In a two-stage system, there are two compressors and two sets of condenser and evaporator coils.

- The refrigerant goes through a high-pressure stage and then a low-pressure stage, allowing for improved efficiency.

- Commonly used in commercial refrigeration and air conditioning systems.

- Cascade Vapor Compression System:

- In a cascade system, two separate refrigeration cycles with different refrigerants are used.

- One cycle operates at a higher temperature, and its condenser rejects heat to the evaporator of the second cycle, which operates at a lower temperature.

- Suitable for applications requiring a wide range of temperature differences, such as industrial processes and low-temperature applications.

- Absorption Refrigeration System:

- In an absorption system, the compressor is replaced by an absorber, pump, and generator.

- It uses a working pair of substances (absorbent and refrigerant) that have different boiling points.

- Absorption systems are often used in niche applications and areas with a waste heat source, like solar absorption refrigeration.

- Vapor Compression Heat Pump:

- A heat pump is a variation of the vapor compression system that can provide both heating and cooling.

- During cooling mode, it operates like a typical vapor compression refrigeration system, but during heating mode, the roles of the evaporator and condenser are reversed.

- Variable Refrigerant Flow (VRF) System:

- VRF systems use multiple indoor evaporator units connected to a single outdoor condenser unit.

- These systems can vary the refrigerant flow to each indoor unit independently, providing precise control and zoning for different spaces.

- Commonly used in commercial and residential buildings.

- Heat Recovery Vapor Compression System:

- This type of system can recover and reuse waste heat from one part of the system for heating in another part.

- It is energy-efficient and often used in buildings where simultaneous heating and cooling are required.

These are just a few examples of the various vapor compression refrigeration system configurations. The choice of a specific type depends on factors such as the intended application, capacity requirements, efficiency considerations, and the need for temperature control.

Advantages of Simple Vapour Compression Refrigeration systems

Simple vapor compression refrigeration systems offer several advantages, making them widely used in various applications for cooling and air conditioning. Here are some key advantages:

- Efficiency:

- Vapor compression systems are known for their high efficiency in transferring heat.

- The compression and expansion processes allow for effective heat absorption in the evaporator and heat rejection in the condenser.

- Versatility:

- These systems can be adapted for various cooling applications, from small household refrigerators to large industrial air conditioning units.

- The technology is versatile and scalable to meet different capacity and temperature requirements.

- Reliability:

- Simple vapor compression systems have been refined over many years, resulting in reliable and well-understood technology.

- Manufacturers have developed robust and durable components, contributing to the overall reliability of these systems.

- Wide Temperature Range:

- Vapor compression refrigeration systems can operate over a wide range of temperatures, making them suitable for both cooling and freezing applications.

- They are capable of maintaining consistent temperatures in diverse environments.

- Cost-Effectiveness:

- The manufacturing and installation costs of simple vapor compression systems are often lower compared to alternative refrigeration technologies.

- Standardization of components and widespread use contribute to cost-effectiveness.

- Ease of Control:

- These systems are relatively easy to control and can be adapted to different control strategies.

- Temperature and pressure can be controlled with precision, allowing for efficient operation and temperature regulation.

- Energy Efficiency:

- While energy consumption depends on factors like system design and operating conditions, vapor compression systems can achieve high levels of energy efficiency.

- Improvements in design and the use of energy-efficient components contribute to reduced energy consumption.

- Commonly Available Refrigerants:

- A variety of refrigerants compatible with vapor compression systems are readily available.

- The choice of refrigerant depends on factors such as environmental considerations, safety, and efficiency.

- Compact Design:

- Vapor compression systems can be designed in compact configurations, making them suitable for applications with limited space, such as residential air conditioners and refrigerators.

- Well-Established Technology:

- Vapor compression technology is well-established and widely understood by engineers and technicians.

- This familiarity simplifies maintenance, troubleshooting, and repairs.

Despite these advantages, it’s essential to note that there are environmental concerns related to the use of certain refrigerants in vapor compression systems. Ongoing efforts in the industry aim to develop and adopt refrigerants with lower environmental impact, promoting sustainability in cooling technologies.

Disadvantages of Simple Vapour Compression Refrigeration systems

While simple vapor compression refrigeration systems have numerous advantages, they also come with certain disadvantages. Here are some common drawbacks associated with these systems:

- Environmental Impact:

- Many traditional refrigerants used in vapor compression systems, such as hydrofluorocarbons (HFCs), contribute to global warming and ozone depletion.

- Phasing out these environmentally harmful refrigerants has led to the development of alternative, more environmentally friendly options.

- Energy Consumption:

- Vapor compression systems can be energy-intensive, especially during peak demand periods.

- The high power requirements of the compressor contribute to increased energy consumption.

- Complex Maintenance:

- While the technology is well-established, certain components, especially compressors, can be complex to maintain.

- Maintenance may require specialized knowledge and equipment.

- Limited Efficiency at Low Loads:

- Vapor compression systems may operate less efficiently at partial loads or during periods of low demand.

- This inefficiency can occur because the system may not modulate well to match the lower cooling or refrigeration requirements.

- Limited Temperature Range:

- While vapor compression systems can handle a wide temperature range, extreme low-temperature applications, such as cryogenic cooling, may require alternative technologies.

- Potential for Refrigerant Leaks:

- Refrigerant leaks can occur over time, leading to both environmental concerns and a reduction in system efficiency.

- Addressing and repairing leaks can be challenging and may require specialized equipment.

- Noise Levels:

- The operation of compressors in vapor compression systems can generate noise, especially in large-scale applications.

- Noise reduction measures may be required in certain environments.

- Initial Cost:

- The upfront cost of installing vapor compression systems can be relatively high, especially for large-scale or industrial applications.

- While the systems are cost-effective over their operational life, the initial investment may be a barrier for some users.

- Cyclic Performance Variation:

- The performance of vapor compression systems can vary cyclically due to changes in operating conditions.

- This may lead to fluctuations in efficiency and performance over time.

- Dependence on Electricity:

- Vapor compression systems are dependent on a reliable electricity supply.

- Power outages or disruptions can affect the system’s ability to maintain proper cooling or refrigeration.

Efforts are ongoing in the industry to address these disadvantages, with a focus on developing more energy-efficient systems, adopting environmentally friendly refrigerants, and improving overall sustainability. Advances in technology, research, and regulations are driving the evolution of vapor compression systems to mitigate their drawbacks.

Frequently Asked Questions – FAQ’s

How do vapor compression systems contribute to energy consumption in buildings?

While they can be energy-intensive, advancements in technology and the use of energy-efficient components aim to reduce the overall energy consumption of vapor compression systems in buildings.

What factors influence the energy efficiency of a vapor compression refrigeration system?

Factors include the design, insulation, and proper sizing of the system, as well as the choice of an energy-efficient compressor and refrigerant.

Are all refrigerants used in vapor compression systems environmentally friendly?

No, some traditional refrigerants, such as hydrofluorocarbons (HFCs), have environmental concerns. Efforts are ongoing to transition to more environmentally friendly alternatives.

Can vapor compression systems be used for both cooling and heating?

Yes, vapor compression heat pump systems can provide both cooling and heating by reversing the roles of the evaporator and condenser.

What is the purpose of the refrigerant in the system?

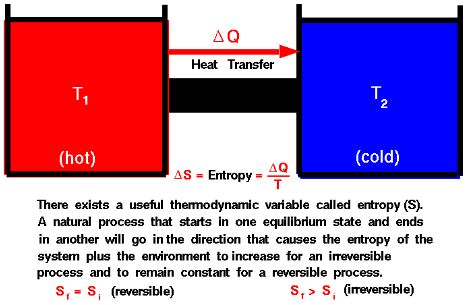

The refrigerant is a fluid that undergoes phase changes in the cyclic process, absorbing heat in the evaporator and releasing it in the condenser to achieve cooling.

What is the role of the compressor in a vapor compression system?

The compressor increases the pressure and temperature of the refrigerant vapor, facilitating the transfer of heat. It plays a crucial role in maintaining the cycle.

Why is the condenser located outside the space being cooled?

The condenser releases heat to the surrounding environment. Locating it outside ensures efficient heat dissipation and prevents the heated air from affecting the cooling space.

What happens in the evaporator during the refrigeration cycle?

The evaporator absorbs heat from the space to be cooled, causing the refrigerant to evaporate and turn into a low-pressure vapor.

How does the expansion valve contribute to the refrigeration process?

The expansion valve reduces the pressure of the refrigerant, causing it to undergo a sudden drop in temperature. This prepares the refrigerant for the next cycle in the evaporator.

How does a simple vapor compression refrigeration system work?

The system works through a cyclic process involving a compressor, condenser, expansion valve, and evaporator. It transfers heat from a low-temperature space to a higher-temperature space, allowing for cooling or refrigeration.