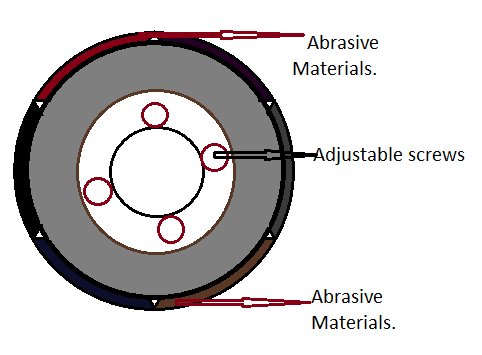

Grinding wheel:

Grinding wheel: In this article we will discuss about how grinding wheels are made, what is grinding wheel and what materials are used in grinding wheels. Grinding wheel is the hardest tool used to remove the metal from cutting tools, tough materials etc.To remove the hard material from the cutting tool, a grinding wheel should be made with the hardest materials. There are commonly two types of materials to get the required wheel they are Natural Abrasive Materials and Artificial Abrasive Materials.

Types Materials used in Manufacturing Grinding Wheels:

There are two types of Materials used in manufacturing Grinding Wheels they are as follows

- Natural Abrasive Materials

- Artificial Abrasive Materials

Natural Abrasive materials:

Natural Aluminium Oxide:

This material is a natural one, which has more than 50% of crystalline alumina.

Diamond:

This material is the hardest material on earth. grinding wheels made form it has a high cutting ability, low wear, and this material has a low rate of heat generation at the time of the cutting process.

Corundum:

This material contains more than 80% of crystalline aluminum, due to this property it consists of high abrasive action and high hardness.

Artificial abrasive materials:

These materials are the hardest materials than natural materials but diamond places first in it.

Aluminum Oxide:

This material is one of the tough material used in grinding wheel, this is mostly used for grinding carbon steel, wrought iron etc.

Silicon Carbide:

It has more brittleness, hardness. this material has some different qualities to grind tough metals like grey cast iron, copper, bronze etc.

Boron carbide:

The combinations of both boric acid and coke at high temperature to obtain high hardness that required to grind hard metals.