Hole Basis System and Shaft Basis System

Hole Basis System and Shaft Basis System: We are going to learn about Hole Basis System and Shaft Basis System, which are used in machine design process, and they must designed and manufactured with high accurate because the defects may causes huge damage, when this manufactured items are used.

Hole Basis System and Shaft Basis System are two different components combined together to make the machine. These two components hole basis and shaft basis have different functions.

Hole basis System: In Hole basis System term hole refers not only the diameter of a circular hole but also to any internal dimensions of a component. When an assembly is made of two parts one is shaft and other is hole.

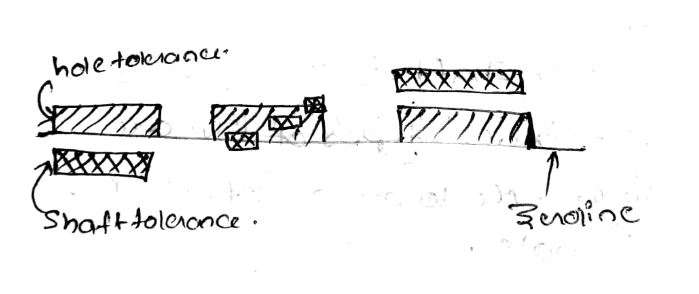

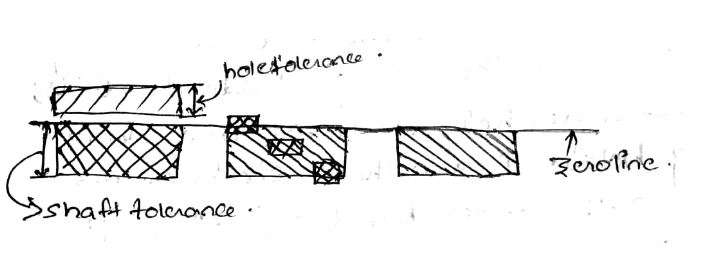

Hole basis system:

- In Hole basis system the hole is kept to constant and the shaft size is changed according to the different types of fit.

- In this method, depending upon the basis size lower limit follows the size of basis, this is due to the lower deviation of the hole is zero in this system.

- The hole basis system is most commonly used because it is more convenient to make of fixed size since standard drills hammers and roaches are available for producing hole and there size are not adjusted on the other hand size are not produced by turning, grinding etc.

Shaft basis system:

Shaft basis system: In Shaft basis system the term shaft refers to both the diameter of a circular shaft and to any external dimensions of a component.

Shaft basis system:

In this system, the shaft is kept constant and the size of the hole is varied to view various types of fits, in this system the upper deviation of the shaft is zero.

Shaft basis system is used when the ground basis is readily available, these bars do not required future machining and fits are obtained by combining with different size of the hole.

Please Subscribe! and Don’t forget to Follow us on Facebook, Twitter, Linkedin, Instagram and Google Plus.