Electron Beam Machining – Principle, Construction, Working of Electron Beam Machining

What is Electron Beam Machining?

Electron Beam Machining: In this article you will know about Electron Beam Machining. Electron Beam Machining is invented by K.H Steiger Wald, in the year 1952 in Germany. Electron Beam Machining is the process is done by high-velocity electrons developed in the electron gun. by converting the electrons kinetic energy into heat energy and helps to melt the metal to do work on it. Electron Beam Machining remove the extra metal from the work piece, this is used in different operations like cutting, drilling etc.

Principle of Electron Beam Machining:

- This is used to remove the extra metal from the work piece, this is used in different operations like cutting, drilling, boring etc.

- This process is done by high-velocity electrons developed in the electron gun. by converting the electrons kinetic energy into heat energy and helps to melt the metal to do work on it.

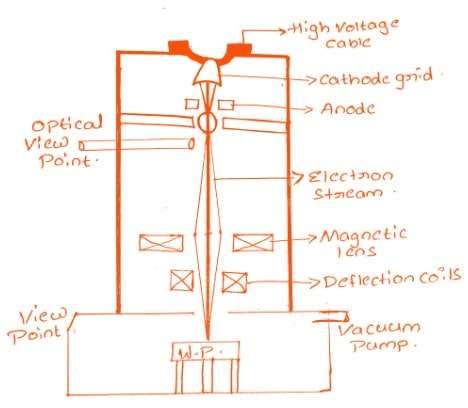

Construction of Electron Beam Machining:

The main pats in the Electron Beam Machining are Electron Gun, Magnetic Gun, Magnetic Lense, Electromagnetic lenses, deflection coils.

Electron Gun:

- This is one of the important elements in the machining process, it is a cathode ray tube which produces the electrons in this and supply with high velocity.

Magnetic Lenses:

- The emitted electron has both divergent and convergent electrons and also low energy electrons. these lenses used to allow only convergent electrons to the next step.

Electromagnetic lenses:

- This used to work on a required spot, and with a thin diameter.

Deflection coils:

- This makes the beam to not deflect in any direction.

Working of Electron Beam Machining:

- Electron beam machine works when the electron gun generates electrons with high-velocity output and reaches to the anode which is arranged below the cathode,

- After passing into it enters into magnetic lenses to filter the electrons, only the convergent electrons are used to pass through it and flow through electromagnetic deflection to get in a required path and enters deflection coil to get these high-velocity electrons to get strikes on the required area, by this high-velocity electrons strikes on work piece gets heated and removes the metal by melting.

Advantages of Electron Beam Machining:

- It can produce a high surface finish.

- Work done by this machining is highly accurate.

- It can machine small diameter holes.

- High drilling rates are available.

- Any material can be machined.

Disadvantages of Electron Beam Machining:

- This can only remove less amount of material from the workpiece.

- more maintenance is required.

- Skilled operated member can only operate.

- Equipment cost is high.