Electric Discharge Machine: Advantages & Disadvantages

Advantages of Electric Discharge Machine:

- The cost of operation is very low.

- The machine can work with metal which has high temperature so it can also be used in a wide range of operations like bending, machining, cutting, etc..

- It works faster than other machines as the friction is reduced by oil flow instead of water and grease.

- There are no risks to the operator while working with this machine as there is no shock or vibration at all during operation.

- It provides an environment free from any environmental contamination and has a much lower energy consumption than conventional machining processes.

- It can produce intricate shapes which are not possible with conventional cutting methods due to limitations in precision and tooling.

- The part gets polished without removing any material and thus no waste product is produced in the process.

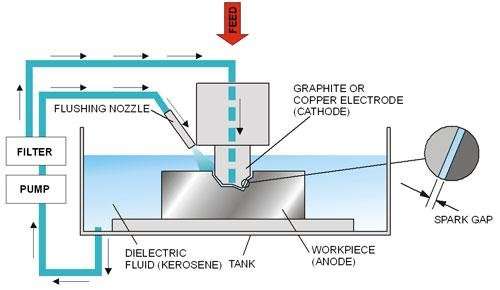

Image Source: Click Here

Disadvantages of Electric Discharge Machine:

- It requires knowledge about operating machinery.

- It requires specialized tools for its functioning and proper maintenance.

- It does not accept different types of materials like rubber, plastics, etc.

- The noise level produced by this type of machine is very high.

- Electricity is the prime power source for this machine, they need more energy to run than most other machines.

- The rotational speeds of these machines are very high leads to noise and vibration.