Difference between Watt Governor and Proell Governor :

Watt Governor:

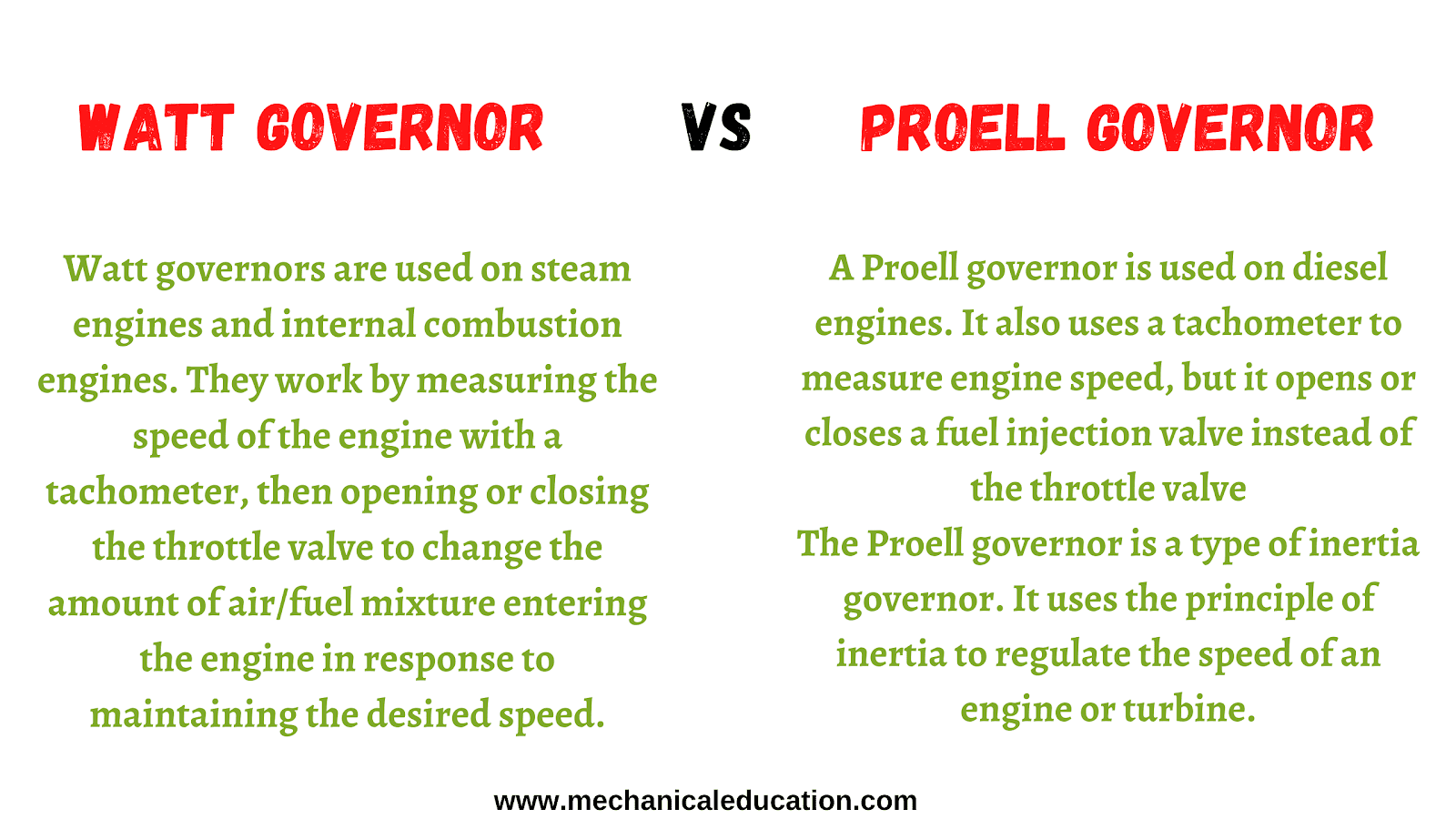

Watt Governors are used on steam engines and internal combustion engines. They work by measuring the speed of the engine with a tachometer, then opening or closing the throttle valve to change the amount of air/fuel mixture entering the engine in response to maintaining the desired speed.

Proell Governor:

A Proell Governor is used on diesel engines. It also uses a tachometer to measure engine speed, but it opens or closes a fuel injection valve instead of the throttle valve.

Difference between Watt governor and Proell Governor:

The Watt Governor is a type of centrifugal governor. It uses the principle of centrifugal force to regulate the speed of an engine or turbine.

The Proell Governor is a type of inertia governor. It uses the principle of inertia to regulate the speed of an engine or turbine.

Watt Governors are used to controlling the speed of an engine by regulating the amount of fuel that is delivered.

Proell Governors are also used to control the speed of an engine, but they do it by cutting off the supply of fuel to the engine.

Watt Governors are more common because they are more efficient – They allow for a smoother running engine.

Proell Governors are used in situations where it is important to have very precise control over the speed of the engine. For example, in a machine that needs to start and stop very quickly, or in a situation where there is a lot of vibration.

The Watt Governor is a more basic and less efficient design than the Proell Governor.

The Watt Governor is a less efficient design because it uses airflow to determine speed while the Proell Governor uses pressure.

The watt governor is also less reliable because it has moving parts that can wear down over time. The Proell Governor does not have any moving parts and is, therefore, more reliable.

The Proell Governor can achieve the same results as a watt governor using only air pressure and without any moving parts.

The Watt Governor consists of a rotating vane just outside the engine combustion chamber with an opening that allows for air to enter or leave. An increase in speed causes increased airflow which creates more force on the vane to move it away from the opening, allowing less air into the engine. The opposite happens when decreasing speed. This change of airflow within the engine causes a change in speed. Demand for more or less power from the engine is accomplished by opening or closing the air valve faster or slower using an accelerator linkage that pulls on a lever inside the governor housing.

A Propell Governor utilizes pressure to determine when to open and close the air supply mechanism. Air moves through a pipe from a separate housing that contains an empty chamber with a diaphragm adhered to the center. The chamber is open at one end and closed at the other with a small orifice leading into the pipe. An increase in engine speed causes increased pressure on the diaphragm which squeezes against the orifice causing airflow out of the chamber and into the pipe. The opposite happens when decreasing engine speed. This change in airflow creates a change in pressure which is sensed by the Proell Governor. This pressure change is what tells the Proell Governor to open or close the air supply to the engine.