Difference between Jig and Fixture?

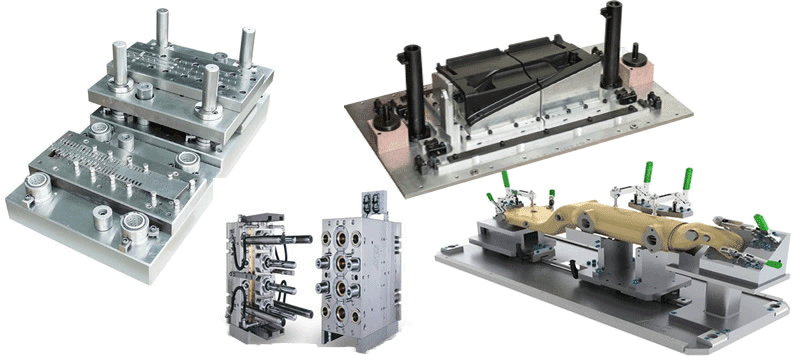

Jigs and fixtures are the most common types of tooling used in manufacturing. They can be used to produce precision-cut parts for the metalworking, woodworking, injection molding, etc.

Jigs and fixtures are used in the manufacturing industry to create precise, repeatable mechanical movements. They allow a machine or tool to move in multiple directions at once while being rigidly fixed into place.

What are Jigs?

A jig is a tool to keep things aligned when you are working on something and it holds, supports the workpiece, and guides cutting tools to perform a required operation. A jig is a tool that helps you to build complex pieces in the metal industry. Jigs are used for holding various types of parts and components together while assembling them, so they can be bolted or welded together at the final stage.

What are Fixtures?

Fixtures are the work holding tool that supports, and direct the workpiece but do not guide the cutting tool to perform a required operation. Fixtures are tools used to hold specific items in place when welding or cutting them.

Fixtures are tools used for holding parts while they are being machined by an industrial robot arm or other types of machines during the manufacturing process. Fixtures usually have adjustable features that help you align parts so that they get machined at right angles to each other thereby reducing inaccuracies in measurement.

Differences between Jigs and Fixtures?

jigs help in precision while fixtures can be used for mass production.

The fixture provides support for transferring motion from one location to another which makes it essential in creating complex designs with high accuracy.

Jigs can guide the cutting tool but fixtures cannot guide the cutting tool.

A jig is a tool that is used to design the 3D model of your product. It can be used to manufacture plastic parts, injection molding, metal casting, machining, and assembly operations.

Jigs are used for unidimensional purposes and fixtures are used for multidimensional.

Jigs are mostly used for manufacturing parts that cannot be manufactured by other methods like die-casting or forging.

jigs are expensive compared to fixtures.

A jig is a special tool that allows you to make accurate measurements or adjustments for your machine while the fixture holds the part securely in place during the manufacturing process.

Fixtures are different from jigs because they provide accurate positioning of the part during the molding process. They may not be necessary if you do not need high precision or if you can find cheaper alternatives than Jig but it depends on your requirement.

Jigs are used for drilling, boring, tapping, etc

Fixtures are used for shaping, slotting, planning, etc