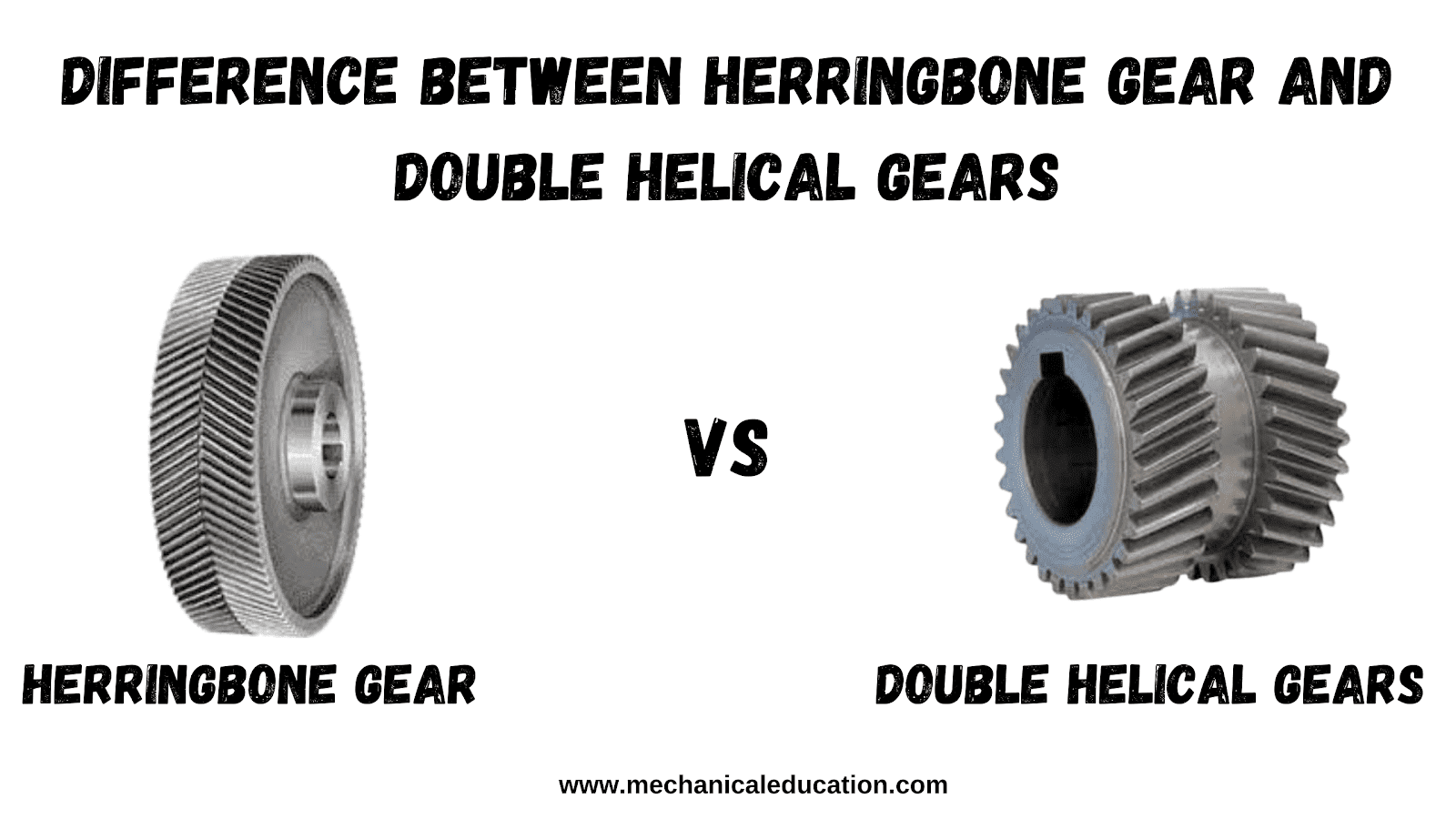

Difference between Herringbone Gear and Double Helical Gear:

The Main difference between Herringbone Gear and double helical Gear are as follows:

- Herringbone gears are gears where the teeth of one gear are set at an angle to the teeth of the mating gear. This angled orientation permits two herringbone gears to mesh together without crossing their paths, which would cause them to jam.

- Herringbone gears are a type of gear system in which the gears are arranged in a chevron pattern. This pattern results in gear with two helical gears that are offset from each other by 90 degrees.

- Helical gears are more compact gear systems with less noise and vibration.

- Herringbone gears are more rigid than double-helical gears because the teeth on one side of the gear do not line up with the teeth on the other side.

- A herringbone gear train is produced by mounting a pinion perpendicular to the axis of a large wheel. A double helical gear train consists of two matching courses of gears. One course has continuous teeth and the other course has interlocking yet different shaped teeth with gaps in between such that an output shaft extends through the entire space created by both courses.

- Herringbone gears are so named because their teeth look like the skeleton of a herring fish. They have two V-shaped teeth set at angles to each other, with the center of each tooth aligned along the common axis of rotation.

- Herringbone gears are often used in low-speed, high torque applications.

- The differences between the two gears are the number of teeth (double helical gears typically have more teeth) and, sometimes, if they are stationary or rotating.

- Herringbone gears are involute, meaning the gear teeth are curved in a way that makes them mesh perfectly with one another. Double helical gears, on the other hand, are not involute, which can make them less efficient. However, because double-helical gears have more contact points between the gear teeth than herringbone gears.

- Double helical gears, also known as spiral bevel gears, are similar to herringbone gears but have two sets of helices that are set at an angle to each other.

- Double helical gears are a special type of herringbone gear where the two sets of angled teeth are offset by half a tooth.

- Double helical gears allow for smoother engagement.

- Double helical gears are often used in high-speed applications as it can handle more power and it’s quieter than a herringbone gear.

- Double helical gears look like two screws threading into each other. They have multiple helical (screwlike) grooves on the faces of their teeth that cause them to mesh together tightly.

- Double helix gears also experience much less wear because nothing is chasing adjacent tooth surfaces but air. They’re quieter because there’s no metal-to-metal rubbing required to generate that “grinding” sound that you get on a car going over a pothole or train going into a station.”

- Double-helical gears are less likely to slip and cause damage than Herringbone gears.