Crankshaft Grinder Machine:

Crankshaft Grinder Machine: This machine is used to grind and shape the crankshaft, the crankshaft is one of the main parts of the engine and plays a major role in transforming the linear motion of piston rod into circular motion. crankshaft shaft should be light in weight and consist of high strength. Grinding the crankshaft should be accurate with the high surface finish is needed and there should be high dimensional tolerance. Crankshaft grinder consists of the grinding wheel that contains abrasive particles on it to remove the extra material from the workpiece.

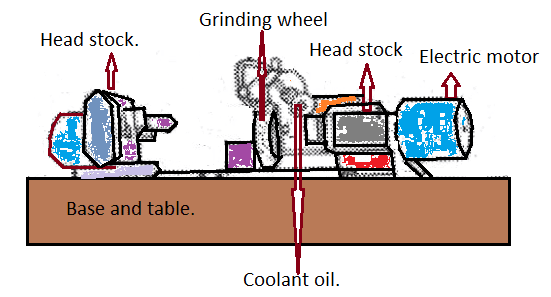

Parts of crank shaft grinder:

Bed:

A bed is the long length part of the machine to support and hold all parts on it for machining purpose.

Electric motor:

This is a three-phase electric motor used to rotate the work placed on it.

Grinding wheel:

Grinding wheel is a cutting tool contains abrasive particles on it to remove the extra material on a workpiece.

Chucks:

This is used to hold the workpiece at the cutting process, which is present at the front of the headstock.

Coolant unit:

Coolant is used to decrease the temperature of the workpiece. the temperature between the grinding wheel and work increases due to continuous or high cutting speed.

Headstock:

It holds main parts like chuck, coolant supply, a rotating spindle of electric motor etc in it.