Centrifugal casting, Advantages, disadvantages and applications.

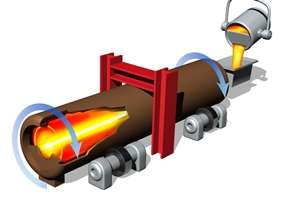

Centrifugal casting: The centrifugal casting is one of the main casting process and little different type of method used to manufacture a product by creating a centrifugal force, This type of force is obtained by a rotating the casting product on a table with high speed. centrifugal force plays an important role to obtain a hallow, cylindrical shapes with clear and accurate dimensions.

In this process, the revolving table creates a centrifugal force and with the help of this force the molten material used to spread over the required shape of the pattern present in it.

Working:

In centrifugal casting operation, casting is done by creating a centrifugal force. the required force is obtained by rotating the mold with high speed at its axis. the rotation of mold is done in a vertical/horizontal direction when this mold made to rotate the molten metal is poured into a mold, this molten metal used to spread on the surface of the cavity, this molten metal spreads over a required with the help of centrifugal force created by the rotation of the mold.

Advantages:

*) The object obtained has no cores in hallow shapes.

*) Centrifugal casting eliminates the impurities in molten metal.

*) This type of products has high density.

*) This manufacturing method increases the mechanical strength.

Disadvantages:

*) Product obtained from this casting process required additional finishing.

*) This method of casting is not so useful for different types of alloys.

*) High accuracy cannot be obtained.

Applications:

This type of casting is highly useful in making pipes, rollers, liners, flywheels etc.