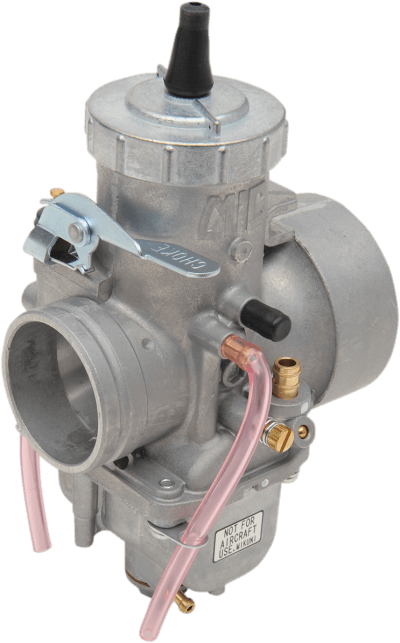

Advantages and Disadvantages of Carburettor?

Advantages of Carburettor:

- Easier to maintain than fuel injection systems.

- Inexpensive to manufacture.

- Simple construction allows for high reliability.

- Easy to modify or repair.

- Low cost per unit displacement compared to fuel injection systems.

- Better performance at altitudes above 3,000 meters (10,000 feet).

- They are relatively simple devices.

- A carburetor’s fuel that enters into intake ports is being mixed by mechanical configuration only, but aspiration assists that process too. This process gives the advantage of quick reaction times, while fuel injection relies on valve timing at throttle position so there are five times more moving parts while needing less pressure overall.

- They can be adjusted to provide the correct air/fuel mixture for different engine conditions.

- They can provide good fuel economy under light load conditions.

- A carburetor avoids the complex, turbulent fuel-air mix in the intake system which is present with a fuel injection system.

Disadvantages of Carburettor:

- Reduced fuel efficiency compared to fuel injection systems due to incomplete combustion of the air/fuel mixture.

- More sensitive to variations in altitude

- They are not as efficient as fuel injection systems when the engine is under a heavy load.

- They can be difficult to start in cold weather conditions.

- It is a relatively slow reaction time to changes in demand for air and momentum changes – this leads to jetting troubles during acceleration because it takes several seconds for the needle to react.

- Fuel wastage is more compared to fuel injectors.