A draft tube is an essential component in the design of reaction turbines used in hydropower plants. Its primary function is to enhance the efficiency of the turbine by recovering kinetic energy from the exiting water and converting it into potential energy. The draft tube is located at the outlet of the turbine runner and serves to increase the pressure at the exit, thereby reducing the exit velocity of the water. This reduction in velocity minimizes energy losses and contributes to the overall performance of the hydroelectric system.

What is a Draft Tube?

A draft tube is a special tube that connects the end of a water turbine to the water channel that carries the water away. This channel is called the tailrace. The draft tube is usually found at the turbine’s exit and helps change the fast-moving water from the turbine into still pressure. It’s like a pathway for the water to leave the turbine smoothly. Draft tubes are typically made of materials like cast steel or concrete.

There are different types of draft tubes. The four main types include:

- Conical draft tube

- Simple elbow draft tube

- Moody spreading draft tube

- Elbow draft tube with a varying cross-section

Let’s explore each type of draft tube in more detail:

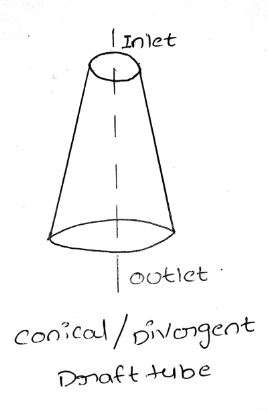

1. Conical Draft Tube:

- Description: The conical draft tube is shaped like a cone, gradually expanding from the narrow end at the turbine exit to a wider end at the tailrace.

- Function: This design allows for a smooth and gradual reduction in water velocity, converting kinetic energy into potential energy. It helps in minimizing energy losses and improving the overall efficiency of the turbine system.

- Application: Conical draft tubes are commonly used in hydroelectric power plants where the head (vertical distance between water intake and turbine exit) is relatively high.

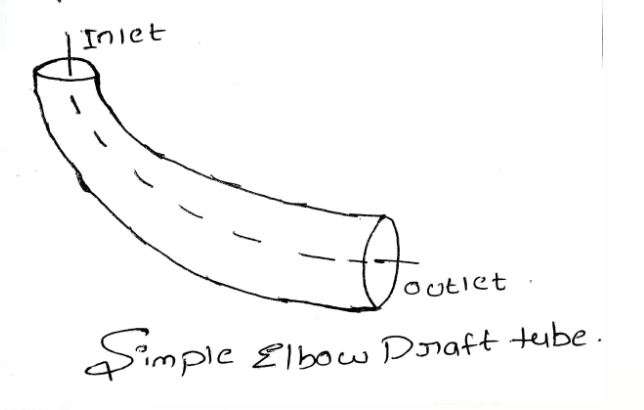

2. Simple Elbow Draft Tube:

- Description: The simple elbow draft tube has a basic elbow-shaped configuration, providing a simple way to redirect the flow of water from the turbine exit to the tailrace.

- Function: It aids in reducing the water’s velocity and recovering some of its kinetic energy as potential energy. The design is straightforward and suitable for installations with less space or lower head conditions.

- Application: Simple elbow draft tubes are often used in situations where a compact design is required or in low-head hydroelectric systems.

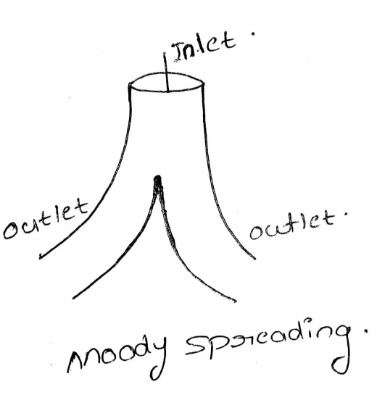

Moody Spreading Draft Tube:

- Description: The Moody spreading draft tube is characterized by its gradually expanding shape, similar to the conical draft tube. However, it may have additional features for enhanced performance.

- Function: This draft tube design aims to further control the flow and pressure distribution, improving efficiency. It helps in preventing cavitation and optimizing energy recovery.

- Application: Moody spreading draft tubes are employed in various hydroelectric plants where specific flow control and pressure considerations are crucial.

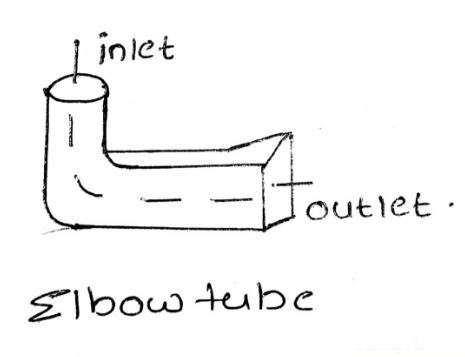

Elbow Draft Tube with Varying Cross-Section:

- Description: This type of draft tube combines the elbow shape with a varying cross-section along its length. It may have sections that widen or narrow, providing a customized approach to pressure recovery.

- Function: The varying cross-section helps in optimizing the conversion of kinetic energy to potential energy, addressing specific flow characteristics. It contributes to better efficiency and performance.

- Application: Elbow draft tubes with varying cross-sections are utilized in hydroelectric systems where tailrace conditions and flow patterns require a more tailored design for optimal results.

In summary, these different types of draft tubes offer engineers and designers flexibility in choosing the most suitable configuration based on factors such as head, available space, and desired efficiency. Each type is tailored to address specific challenges and optimize the performance of the hydroelectric turbine system.

Here’s a detailed explanation of the features and functions of a draft tube:

- Purpose of the Draft Tube:

- The primary purpose of the draft tube is to recover kinetic energy from the high-velocity water leaving the turbine runner.

- By slowing down the speed of the exiting water, the draft tube converts some of its kinetic energy into potential energy, which can be harnessed for further power generation.

- Location and Connection:

- The draft tube is typically connected to the outlet of the turbine runner and extends downstream towards the tailrace or discharge point.

- It is an integral part of the hydraulic circuit of the turbine system.

- Gradual Increase in Area:

- The cross-sectional area of the draft tube gradually increases from the inlet (at the turbine runner exit) to the outlet (at the discharge point).

- This gradual expansion is designed to accommodate the diverging flow of water and facilitate a smooth reduction in velocity, thereby increasing pressure.

- Types of Draft Tubes:

- There are different types of draft tubes, such as straight draft tubes and curved draft tubes, depending on the turbine design and installation requirements.

- The choice of draft tube type is influenced by factors like available space, head (vertical distance between the water intake and turbine outlet), and overall system efficiency considerations.

- Improvement in Output and Efficiency:

- The implementation of a draft tube significantly improves the overall efficiency of the hydroelectric system.

- By recovering kinetic energy and minimizing energy losses, the draft tube contributes to higher turbine performance and increased power output.

- Cavitation Prevention:

- The design of the draft tube helps in preventing cavitation, a phenomenon where the pressure of the flowing water drops below the vapor pressure, leading to the formation of vapor bubbles.

- Cavitation can cause damage to turbine components, and the draft tube plays a role in maintaining adequate pressure to avoid this issue.

In summary, a draft tube is a crucial component in the design of reaction turbines in hydropower plants. Its purpose is to recover kinetic energy from the exiting water, reduce exit velocity, and enhance overall turbine efficiency. The specific design and type of draft tube depend on the characteristics of the hydroelectric system and the turbine being used.

Advantages of Draft Tube

Draft tubes play a crucial role in the efficient operation of hydroelectric turbines, providing several advantages to the overall performance of the system. Here are some key advantages of draft tubes:

- Energy Recovery:

- Draft tubes facilitate the conversion of kinetic energy in the fast-moving water leaving the turbine into potential energy. This energy recovery helps maximize the overall efficiency of the hydroelectric system.

- Increased Pressure:

- By slowing down the velocity of the water at the turbine exit, draft tubes increase the static pressure. This elevation in pressure assists in preventing cavitation and allows for a more controlled and efficient energy conversion process.

- Cavitation Prevention:

- Draft tubes contribute to preventing cavitation, a phenomenon that occurs when the pressure of the water drops to the vapor pressure level, forming vapor bubbles. Cavitation can be damaging to turbine components, and the design of the draft tube helps maintain sufficient pressure levels to avoid this issue.

- Improved Turbine Performance:

- The use of draft tubes enhances the performance of the hydroelectric turbine by providing a smooth pathway for the water to exit. This results in a reduction of energy losses and an increase in the turbine’s overall power output.

- Tailrace Optimization:

- Draft tubes contribute to the controlled discharge of water into the tailrace. This helps optimize the flow patterns in the tailrace, reducing turbulence and improving the overall stability of the system.

- Versatility in Design:

- There are various types of draft tubes, such as conical, simple elbow, Moody spreading, and those with varying cross-sections. This versatility allows engineers to select a design that suits the specific requirements of the hydroelectric plant, taking into consideration factors like head, space constraints, and flow characteristics.

- Prevention of Water Hammer:

- Draft tubes play a role in mitigating water hammer effects, which are sudden pressure surges in the water flow. The design of the draft tube aids in maintaining a more gradual and controlled flow, reducing the likelihood of water hammer-related issues.

- Enhanced System Stability:

- The proper implementation of draft tubes contributes to the stability of the entire hydroelectric system. It helps maintain a steady flow of water, reducing fluctuations and ensuring reliable and consistent power generation.

In summary, draft tubes are essential components in hydroelectric power plants, providing advantages that include energy recovery, increased pressure, prevention of cavitation, improved turbine performance, tailrace optimization, versatility in design, prevention of water hammer, and enhanced system stability. These benefits collectively contribute to the efficiency and reliability of hydroelectric power generation.

Disadvantages of Draft Tube?

While draft tubes offer several advantages in hydroelectric power generation, there are also some potential disadvantages and challenges associated with their use. Here are a few considerations:

- Space Requirements:

- Draft tubes can require a significant amount of space for installation. In situations where space is limited, the design and implementation of draft tubes may become challenging.

- Sensitivity to Design Changes:

- Draft tubes are sensitive to changes in design parameters, such as cross-sectional area and geometry. Small variations in design can impact their performance, potentially leading to efficiency losses.

- Tailrace Environmental Impact:

- The discharge of water into the tailrace through the draft tube can affect the downstream environment. The altered flow patterns and water temperature changes may have ecological implications for aquatic ecosystems.

- Maintenance Challenges:

- Draft tubes, like any other components in a hydroelectric system, require regular maintenance. Issues such as sediment deposition, debris accumulation, or wear and tear can affect their performance, necessitating periodic inspections and maintenance efforts.

- Initial Construction Costs:

- The installation of draft tubes involves additional engineering considerations and costs during the initial construction of a hydroelectric plant. The complexity of the design and construction can contribute to higher upfront expenses.

- Hydraulic Losses:

- Despite efforts to optimize design, some hydraulic losses may occur within the draft tube. These losses can impact the overall efficiency of the energy conversion process and reduce the power output of the turbine.

- Specific Design Requirements:

- Different hydroelectric systems may have specific design requirements, and the selection of an appropriate draft tube type depends on factors such as head, available space, and flow conditions. Tailoring the design to meet these requirements may pose challenges.

- Water Hammer Effects:

- While draft tubes can help mitigate water hammer effects, certain operational conditions or sudden changes in flow may still lead to water hammer-related issues. This can result in pressure surges that could potentially impact the structural integrity of the system.

It’s important to note that while these disadvantages exist, they are often addressed through careful engineering, design considerations, and ongoing maintenance practices. The benefits of draft tubes in terms of energy recovery and overall system efficiency generally outweigh these challenges in well-designed and well-maintained hydroelectric facilities.

Draft Tube Efficiency

The efficiency of a draft tube in a hydroelectric power plant is typically assessed in terms of its ability to recover energy and optimize the overall performance of the turbine. Several factors influence the efficiency of a draft tube:

- Energy Recovery Efficiency:

- The primary purpose of a draft tube is to recover kinetic energy from the high-velocity water leaving the turbine runner and convert it into potential energy. The efficiency of the draft tube is closely tied to how effectively it achieves this energy recovery.

- Pressure Recovery:

- An efficient draft tube is designed to increase the static pressure of the water at the exit, which helps prevent cavitation and contributes to the overall stability of the turbine system. The ability to recover and maintain high pressure levels is indicative of the draft tube’s efficiency.

- Minimization of Energy Losses:

- Draft tubes aim to minimize energy losses in the form of turbulence, vortices, and other hydraulic inefficiencies. An efficient draft tube design provides a smooth pathway for the water to exit the turbine, reducing frictional and other losses.

- Control of Flow Patterns:

- The design of the draft tube influences the flow patterns in the tailrace. An efficient draft tube helps control and optimize these flow patterns, reducing turbulence and ensuring a stable discharge of water.

- Prevention of Cavitation:

- Cavitation, which can occur when water pressure drops below vapor pressure, can be detrimental to the turbine components. An efficient draft tube design prevents cavitation by maintaining adequate pressure levels.

- Tailoring to Specific Conditions:

- Different hydroelectric systems may have specific conditions, such as head, space constraints, and flow characteristics. An efficient draft tube is often tailored to meet these specific conditions, optimizing its performance in the given environment.

- Versatility and Adaptability:

- An efficient draft tube design may exhibit versatility in adapting to varying operating conditions and demands. This adaptability ensures that the draft tube remains effective across a range of scenarios.

It’s important to note that the efficiency of a draft tube is often evaluated within the context of the entire hydroelectric system. While a well-designed and properly functioning draft tube contributes to increased turbine efficiency, overall system performance depends on various factors, including the turbine design, head, flow rate, and the hydraulic characteristics of the entire water conveyance system.

Efforts to enhance draft tube efficiency may involve advanced computational fluid dynamics (CFD) modeling, hydraulic simulations, and optimization techniques during the design phase, as well as regular maintenance and monitoring during operation.