What is Air Refrigeration System?

An air refrigeration system is a type of refrigeration system that uses air as the working fluid to transfer heat and achieve cooling. In these systems, air undergoes a thermodynamic cycle involving compression, cooling, expansion, and heating to accomplish the removal of heat from a particular space or substance.

There are two primary types of air refrigeration systems:

- Bell-Coleman Cycle:

- The Bell-Coleman cycle is an open cycle air refrigeration system that operates based on the principles of air expansion and compression. It is commonly used in aircraft air conditioning systems and portable refrigeration units. The cycle involves processes of compression, cooling, expansion, and heating to achieve the desired refrigeration effect.

- Reverse Brayton Cycle (Air Cycle Refrigeration):

- The Reverse Brayton cycle is another type of air refrigeration system, which is a modification of the Brayton cycle commonly used in gas turbines. In the Reverse Brayton cycle, air is compressed, cooled, expanded, and then heated to achieve refrigeration. This type of system is often found in aircraft air conditioning systems and has applications in certain industrial and commercial cooling scenarios.

The choice between these systems depends on factors such as the specific application, efficiency requirements, weight considerations, and environmental concerns.

It’s important to note that while air refrigeration systems have their advantages, they are not as widely used as vapor compression systems in many refrigeration and air conditioning applications. Vapor compression systems use specific refrigerants and are more prevalent due to their higher efficiency and broader operating range. The selection of a refrigeration system depends on the unique requirements of the application.

Merits and Demerits of Air Refrigeration System

Merits (Advantages) of Air Refrigeration Systems:

- Environmentally Friendly: Air refrigeration systems use air as the working fluid, eliminating the need for synthetic refrigerants with environmental concerns such as ozone depletion and high global warming potential.

- No Refrigerant Leakage Concerns: Unlike systems that use specific refrigerants, air refrigeration systems do not face issues related to refrigerant leakage, reducing environmental impact and safety concerns.

- Simplicity of Design: Air refrigeration systems, especially those based on the Bell-Coleman cycle, are relatively simple in design. This simplicity can lead to easier maintenance and lower installation costs.

- Suitable for Specific Applications: Air refrigeration systems are well-suited for applications where weight is a critical factor, such as in aircraft air conditioning and portable refrigeration units.

- Dry Air Output: Reverse Brayton cycle air refrigeration systems produce dry and cool air, which is beneficial in certain industrial processes and applications where humidity control is essential.

- Rapid Start-Up: Air refrigeration systems can achieve rapid start-up times, making them suitable for applications requiring quick cooling or air conditioning.

- Low Cost for Some Applications: In specific applications where simplicity and lightweight design are prioritized over high efficiency, air refrigeration systems can be cost-effective.

Demerits (Disadvantages) of Air Refrigeration Systems:

- Lower Efficiency: Air refrigeration systems, especially those based on the Bell-Coleman cycle, generally have lower efficiency compared to vapor compression systems. This can result in higher energy consumption for a given cooling capacity.

- Limited Cooling Capacity: The cooling capacity of air refrigeration systems may be limited, particularly when compared to larger vapor compression systems. This can be a drawback in applications with high cooling requirements.

- Temperature Limitations: Air refrigeration systems may have limitations in achieving very low temperatures or a wide range of temperature control, depending on the specific cycle used.

- Complexity in Large Systems: While the Bell-Coleman cycle is simple, larger systems may require multiple compressors and expanders, introducing complexities. In such cases, the simplicity advantage diminishes.

- Maintenance Challenges: Despite the simplicity of design, certain components, such as the expansion turbine, may require careful maintenance to prevent wear and ensure reliable operation.

- Risk of Icing: In certain conditions, there is a risk of ice formation in the expansion turbine, affecting system performance and reliability.

- Dependence on Ambient Conditions: The performance of air refrigeration systems can be influenced by ambient conditions, such as air temperature and humidity. Variations in these conditions can impact the system’s efficiency and cooling capacity.

- Limited to Specific Industries: While suitable for certain industries like aviation, air refrigeration systems may not find widespread use in other sectors due to limitations in efficiency and cooling capacity.

The choice of whether to use an air refrigeration system depends on the specific requirements and constraints of the application at hand, considering factors such as efficiency, weight, environmental impact, and cost.

Methods of Air Refrigeration Systems

There are several methods of air refrigeration systems, each employing different thermodynamic cycles and processes to achieve cooling. Two primary methods are the Bell-Coleman cycle and the Reverse Brayton cycle. Here’s an overview of these methods:

- Bell-Coleman Cycle:

- The Bell-Coleman cycle is an open cycle air refrigeration system commonly used in aircraft air conditioning and portable refrigeration units. The cycle consists of four main processes: compression, cooling, expansion, and heating. The processes involve the use of a compressor, a cooler, an expander, and a regenerator or another heat exchanger. The simplicity of the cycle and its suitability for applications where weight is a critical factor make it advantageous in specific scenarios.

- Reverse Brayton Cycle (Air Cycle Refrigeration):

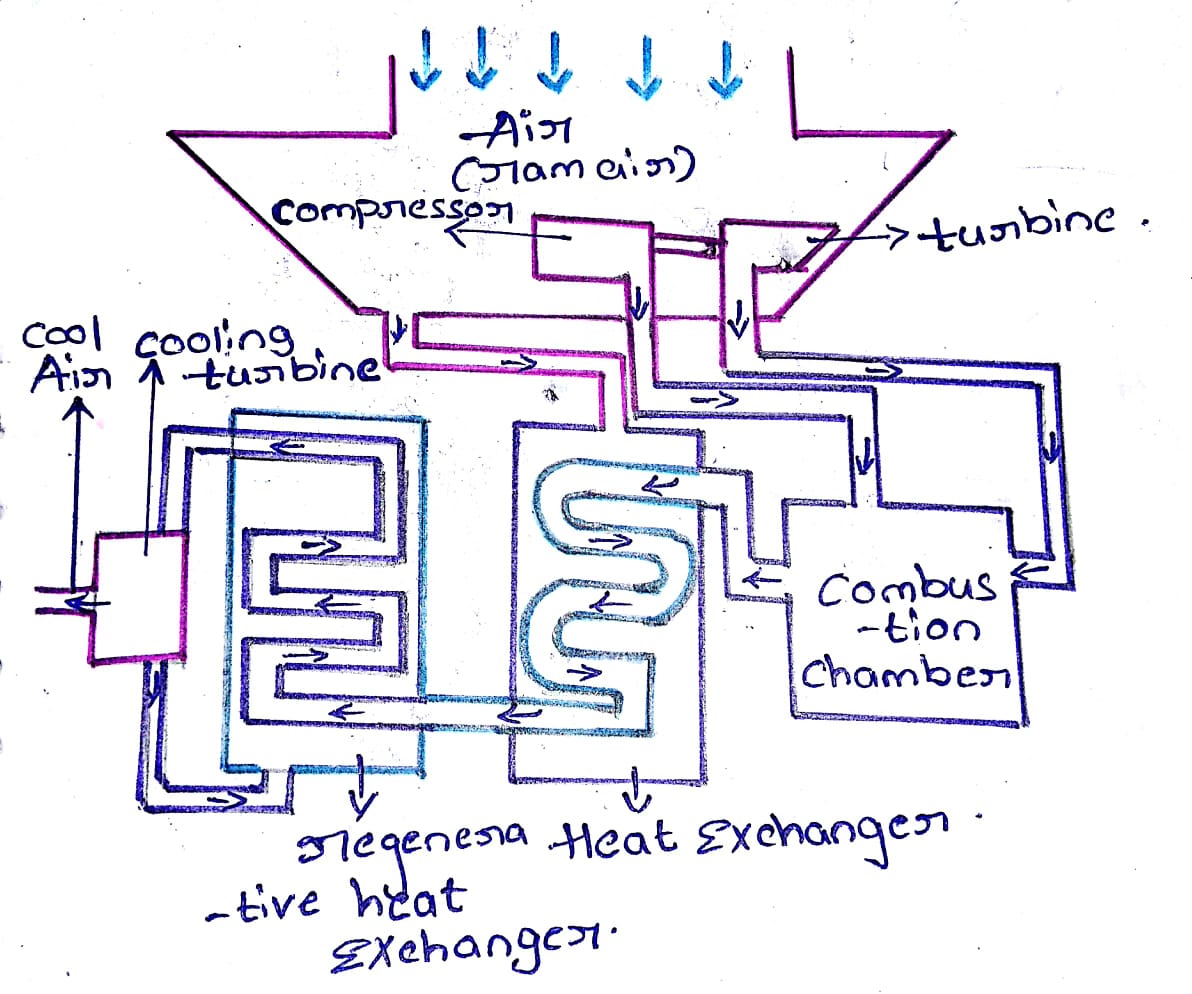

- The Reverse Brayton cycle is another method used in air refrigeration systems, particularly in aircraft air conditioning. It is a modification of the Brayton cycle, which is commonly used in gas turbines. In the Reverse Brayton cycle, air is compressed, cooled, expanded, and then heated to achieve refrigeration. This process typically involves a compressor, an air cooler, an expander, and a heat exchanger. The system produces dry and cool air, making it suitable for certain industrial applications.

- Thermoelectric Refrigeration:

- Thermoelectric refrigeration relies on the Peltier effect, where an electric current is passed through a junction of two different conductive materials, causing a temperature difference. This temperature difference can be used for both heating and cooling. While not as common as vapor compression systems, thermoelectric refrigeration finds applications in smaller-scale cooling devices, such as portable coolers and wine coolers.

- Vortex Tube Refrigeration:

- The vortex tube is a device that separates compressed air into hot and cold streams without any moving parts. Compressed air enters the vortex tube and spirals along the inner walls, creating a temperature gradient. The hot air is expelled through one end, while the cold air exits through the other. Vortex tube refrigeration is simple but is typically used for low-capacity cooling applications.

- Jet Refrigeration:

- Jet refrigeration systems utilize the expansion of a high-pressure refrigerant through a nozzle to produce a low-pressure and low-temperature stream. This stream is then used for cooling purposes. Jet refrigeration systems are not as common as vapor compression systems but have been used in specific applications.

- Desiccant Air Conditioning:

- Desiccant air conditioning systems use desiccants, materials that absorb and remove moisture from the air. These systems often combine desiccant dehumidification with evaporative cooling or other cooling methods to achieve the desired air conditioning effect. They are sometimes used in specialized applications where humidity control is critical.

Each of these methods has its advantages and limitations, and the choice of a particular method depends on the specific requirements, constraints, and application scenarios. Vapor compression systems, using specific refrigerants, remain the most widely used method in various refrigeration and air conditioning applications due to their efficiency and versatility.

Frequently Asked Questions – FAQ’s

In what situations are air refrigeration systems a preferred choice over traditional vapor compression systems?

Air refrigeration systems are preferred in situations where weight is a critical factor, such as in aircraft air conditioning. Their simplicity and environmental friendliness make them suitable for specific niche applications.

What are the challenges associated with maintenance of air refrigeration systems?

While air refrigeration systems are relatively simple, certain components, such as the expansion turbine, may require careful maintenance to prevent wear and ensure reliable operation.

What is the significance of the Reverse Brayton cycle in air refrigeration?

The Reverse Brayton cycle is known for producing dry and cool air, making it suitable for applications like aircraft air conditioning, where the quality of the air is crucial.

Can air refrigeration systems achieve very low temperatures?

The ability to achieve very low temperatures may be limited in air refrigeration systems. The range of achievable temperatures depends on the specific cycle and application.

Are air refrigeration systems as efficient as traditional vapor compression systems?

Generally, air refrigeration systems, especially those based on the Bell-Coleman cycle, have lower efficiency compared to vapor compression systems. However, they are chosen for specific applications where other factors, such as weight, are critical.

What advantages do air refrigeration systems offer in terms of environmental impact?

Air refrigeration systems are environmentally friendly as they use air as the working fluid, eliminating concerns related to synthetic refrigerants with environmental impacts.

Where are air refrigeration systems commonly used?

Air refrigeration systems, such as those based on the Bell-Coleman or Reverse Brayton cycles, are commonly used in aircraft air conditioning, portable refrigeration units, and certain industrial applications.

What are the main components of an air refrigeration system based on the Bell-Coleman cycle?

The main components include a compressor, cooler, expander, and regenerator or another heat exchanger. These components work together to achieve the refrigeration effect.

How does the Bell-Coleman cycle differ from the Reverse Brayton cycle in air refrigeration?

The Bell-Coleman cycle is an open cycle used in aircraft air conditioning, while the Reverse Brayton cycle is a modification of the Brayton cycle used in air cycle refrigeration, producing dry and cool air often in aviation applications.

What is an air refrigeration system?

An air refrigeration system is a type of refrigeration system that uses air as the working fluid to transfer heat and achieve cooling. It involves processes like compression, cooling, expansion, and heating to accomplish refrigeration.