Clamping Devices: Rules and Types of Clamping Devices:

What is a Clamping Device?

Clamping devices are generally used in the manufacturing industry. Clamping devices are used to hold parts together during the manufacturing process. It is a tool that holds parts and helps to make sure they stay fixed and do not move while they are being processed. They are typically designed with one piece of metal that covers the entire opening on the end of the device. A bolt or screw is then tightened down to hold it in place.

Clamping devices can be manual or automatic depending on their purpose. Manual clamps will only allow one person to operate them, while automatic clamps can also perform multiple functions such as moving and positioning parts. A good example of an automatic clamp would be a CNC machine which has its own kind of clamping device that makes it possible for the machine to automatically move different pieces of metal without having to rely on humans doing it manually themselves.

Types of clamping devices:

Clamping devices are used for fastening different components to the part being machined.

Taper tool:

A taper tool is used to quickly form tapers on the end of various components. The taper tool has two handles with an internal ratchet mechanism that allows it to be moved back and forth in order to make smooth transitions between the component being machined and another part or component attached at one end. Taper tools are usually made from hardened steel, but aluminum can also be used if desired.

Forming die:

Forming a die which allows the user to precisely position parts by allowing them to move into place without requiring any additional force or effort other than normal hand pressure exerted on the handle of the forming die. Facing dies are normally composed of hardened steel while facing wheels are often constructed from hardened brass or aluminum.

Jiggs and Fixtures:

Jiggs and Fixtures consists of a piece or multiple pieces that allow parts such as gears and shafts with tapered ends to be securely clamped in place while still allowing them to rotate freely when rotated by hand power tools such as screwdrivers and drill presses

Clamping devices are used in industrial applications such as mining, construction, and maintenance. They help to keep the product from moving when it is in use.

Spring-loaded plate:

The spring-loaded plate is also known as the soft or linear compression system and it consists of a compressed spring that can be easily adjusted with a set screw. It is used for hard to compress materials such as wood, steel, rubber, and plastics.

Hard jaws:

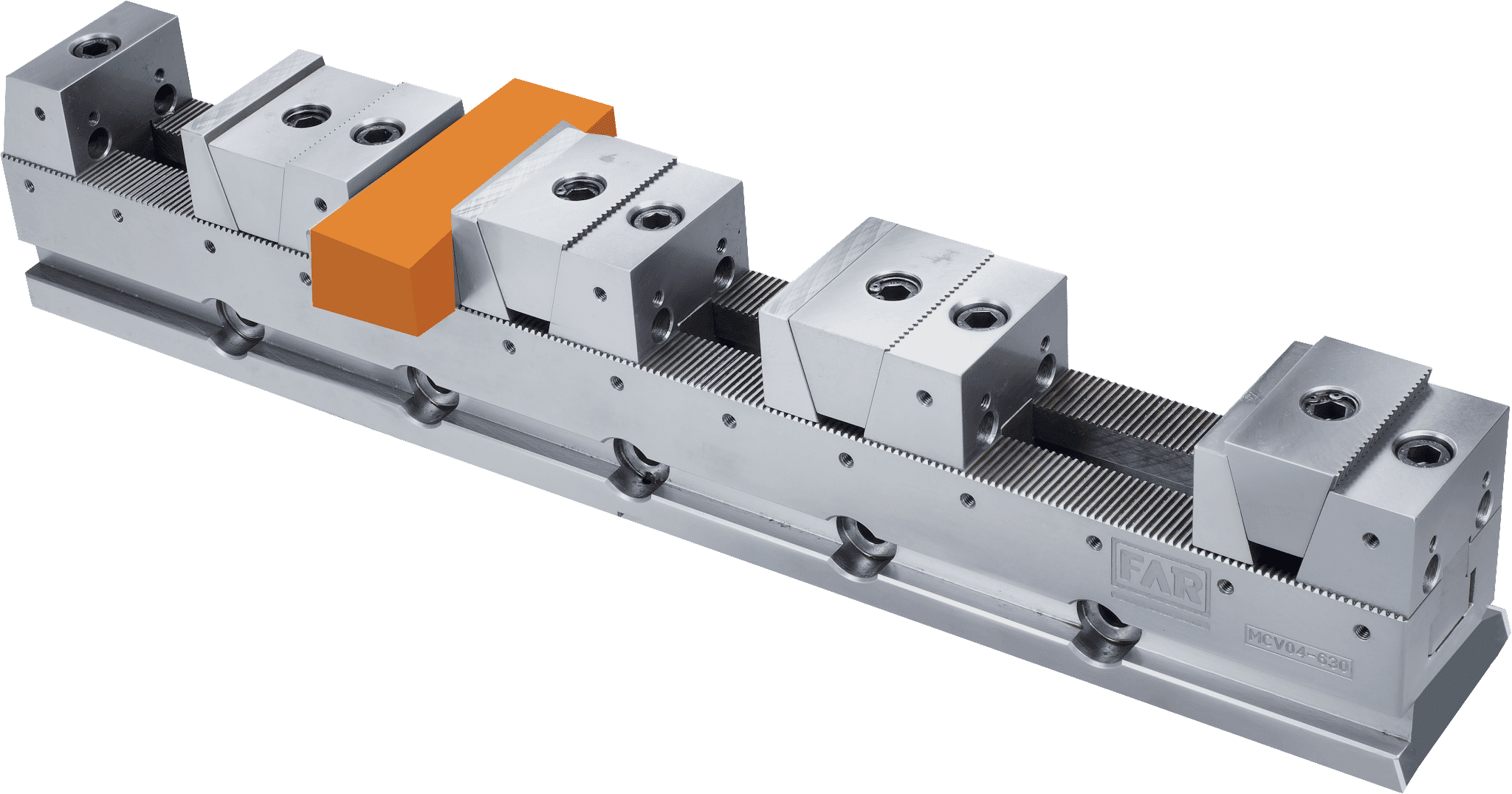

These types of clamps are designed for metals and tough materials like plywood, aluminum, and sheet metal. They usually have two jaw members with one fixed jaw member and another movable jaw member which can open up to 150 degrees so you can reach around corners without having to turn the workpiece over.

Soft jaws:

This type of clamp has soft jaws that are flexible but strong enough to hold most materials including cardboard boxes, fabric packages, plastic bags, etc., It is great for holding things tightly without damaging them too much or bending them out of shape because it uses elasticity for tension control rather than strength. Most models will allow some degree of motion when closed which allows you to get into tight areas where other clamps would not fit.

Spring-loaded and electric-powered:

Spring-loaded clamps have a mechanical advantage that enables them to close tighter than an electric clamp without damaging the clamping surface. The disadvantage is that they require more force to close compared to electric clamps because there is no motorized assistance from the spring mechanism.