Difference Between Stator and Rotor

The terms “Rotor” and “Stator” typically refer to the rotating part of an electric motor, which has blades around it that spin around. It can also refer to rotating turbine blades or other things with spinning objects around them. A stator typically refers to any device or mechanism inside of an electric appliance or machine which stays still while another rotates — such as within weed-eaters, vacuum cleaners, and generators.

What is a Stator?

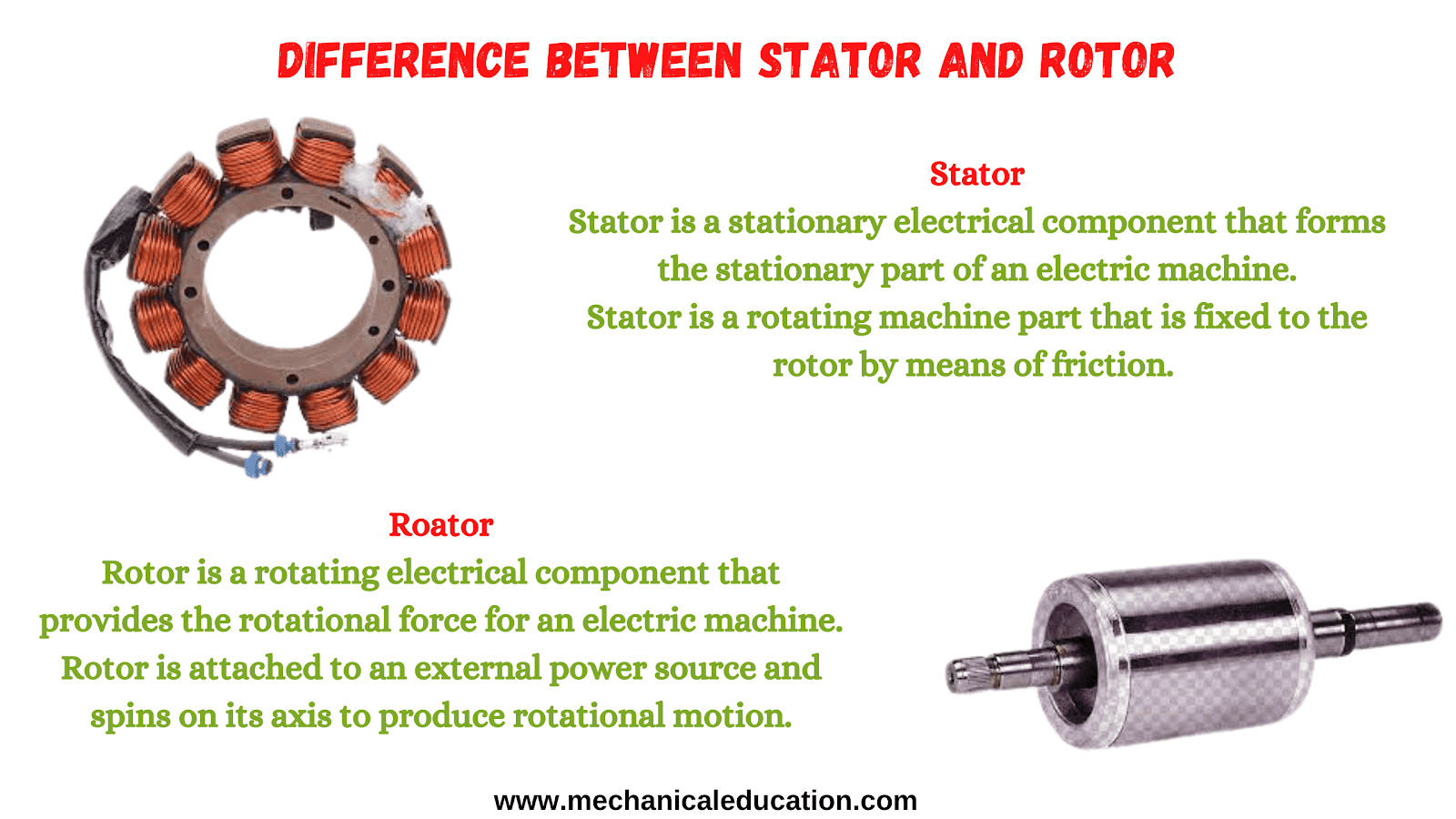

A stator is a stationary electrical component that forms the stationary part of an electric machine.

What is a Rotor?

The rotor is moving parts of an electric motor or mechanism that produce energy, such as a compressor in a refrigerator.

Difference between Stator and Rotor:

Stator is a stationary electrical component that forms the stationary part of an electric machine.

Rotor is a rotating electrical component that provides the rotational force for an electric machine.

Stator is a rotating machine part that is fixed to the rotor by means of friction.

Rotor is attached to an external power source and spins on its axis to produce rotational motion.

Stator is a stationary device that produces a rotating magnetic field in an electric motor.

Stator is the part of a rotating machine that generates torque by changing its magnetic field. Rotor is the stationary part of a rotating machine that receives torque from the stator and converts it into mechanical energy, typically in the form of a circular motion.

Stator is made up of coils that are electrically connected to an external power source and forms a magnetic field in which the rotor can rotate. The rotating motion of the rotor creates electricity as it turns and passes through this magnetic field.

Stator is a stationary part of an electric machine that rotates to change the direction of the magnetic field produced by an electromagnet.

Rotor is the part of the motor that rotates and generates the torque, usually by interacting with a stationary magnet (the stator).

Rotor is a rotating part in an electric machine that changes the direction of the magnetic field produced by an electromagnet.

Motor stator and rotor work together to create the magnetic field. The stator, mounted in a fixed position, has wire coils around it that carry current and produce a magnetic field. The rotor’s job is to use magnetic attraction and repulsion when it moves relative to the stators—so when the motor armature spins within this fixed magnetic axis (solenoid), currents flow through one set of coils in one direction – producing mechanical movement.

Stator is a stationary component while the rotor rotates around it. The main purpose of the rotor is to generate torque, or turning force, to turn the shaft of an electric machine.

In a generator, the stator contains the field winding and armature winding. The rotor typically contains windings to create a rotating magnetic field that induces a voltage in the stator windings.

There are several key differences between the stator and rotor of an electric motor. The stator is the stationary part of the motor, while the rotor is the rotating part. The stator contains the windings that create the magnetic field, while the rotor contains the electromagnets that interact with this field.

The Stator is typically made from a non-conductive material like fiberglass or plastic, while the rotor is made from a conductive metal like copper or aluminum. Finally, the stator is enclosed in a metal casing, while the rotor is exposed to air.

The Stator is the stationary part of an electric machine, while the rotor is the rotating part. In a motor, the stator is the outer casing and contains the windings that generate the magnetic field. The rotor sits inside the stator and has magnets attached to it. When current flows through the windings in the stator, it creates a rotating magnetic field that interacts with the magnets on the rotor, causing it to turn.

Stator is a series of copper wire loops that form the stationary part of a machine, such as a generator or motor. The main function of the stator in a DC electric motor is to keep the rotating armature turning by quickly reversing polarity so that there’s always current moving from one side of each magnet to the other.

The Rotor is what does all the work in an AC-powered device–it’s where electricity comes out and powers anything it passes through on its way out. In other words, it rotates creating electromagnetic fields that produce alternating currents at designated frequencies which are then used commercially.

Stator contains windings that produce a rotating magnetic field (RMF). This RMF interacts with the magnetic fields generated by the current flowing through the windings on the rotor, causing it to rotate. The faster this RMF spins, the more torque it generates on the rotor. So, by adjusting how fast the stator’s RMF spins, you can control how much torque is output.