Advantages & Disadvantages of Cooling System in IC Engine

What is Cooling system in IC Engine?

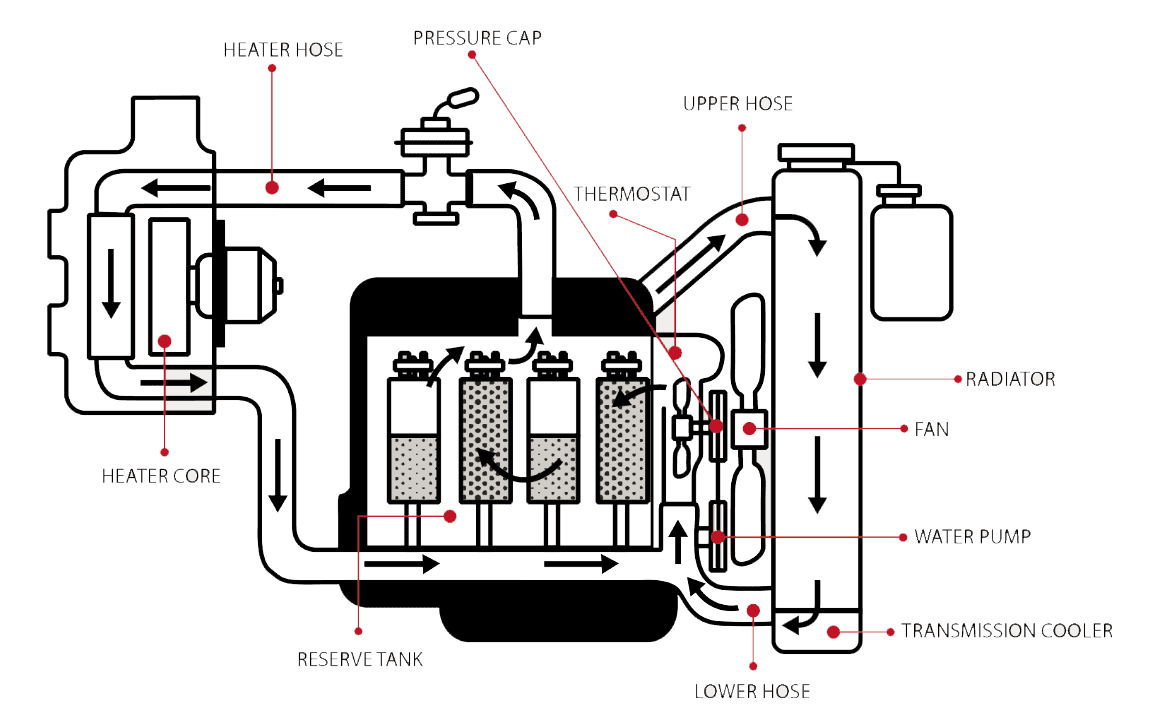

Cooling System is one of the Important part in IC Engine which is to prevent overheating when the combustion takes place in the engine. cooling system makes the engine wok efficiently by maintaining the required temperature with out overheating the engine parts which causes a huge damage to engine. cooling system works by heat transfer method and It helps to maintain correct operating temperature in engine.

Advantages of a cooling system in an internal combustion engine.

- The main advantage of a cooling system in an internal combustion engine is that it helps to keep the engine running at a consistent temperature. This allows the engine to run more efficiently and helps to prevent corrosion.

- It reduces the temperature of the engine and hence increases its life.

- It prevents piston rings, valves, and other parts due to overheating.

- It prevents knocking or pinging noise due to the rise in air-fuel ratio with the temperature rise.

- Efficiency: The cooler the engine is, the less heat it will produce. The engine can run more efficiently and tends less wear and tear.

- Emissions: A cooler engine also produces fewer emissions, which is better for both the environment and public health.

- Performance: The decreased heat output results in an overall improvement in performance.

- Without using a cooling system in the internal combustion engine, it gets overheated and damages the parts of an engine. A cooling system can help to protect the engine from damage in the event of a collision.

- Cooling System makes less maintenance than replacing parts after getting damaged by overheating.

Disadvantages of Cooling System in IC Engine

- It adds an extra weight that they add to the vehicle. This can be a problem, especially in smaller or lighter vehicles.

- Another disadvantage of cooling systems is that they can often be quite expensive to maintain and repair. In addition, if the coolant leaks, it can damage the engine or create a dangerous driving situation.

- This requires a long chassis to accommodate the radiator, thicker radiators for engine protection at high ambient temperature, and heavy-duty mounts to prevent flexing vibration.

- More brake dust from the metal on the metal expansion of the engine, increased exhaust gas temperatures from a large volume of air moving through the engine, power loss due to a decrease in compression ratio, and lower operating temperatures.

- They require a lot of energy to operate, which again reduces fuel efficiency.

- They can break down or malfunction, causing the engine to overheat and potentially fail.

- They can be expensive to maintain and repair.