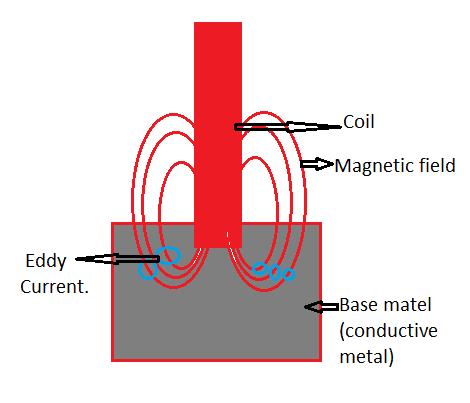

Eddy Current:

Eddy Current: This is the basic principle of Eddy currents gets inducted in the conducting material when there is a current carrying coil present near the conducting material.This inductive material generates the magnetic field by the help of current-carrying coil and this magnetic field acts against the main magnetic field which is developed by the current carrying coil itself and this eddy current get induced by placing the conducting material and the current carrying coil near to each other.

Eddy current converts the kinetic energy into heat and this is applied in many useful applications like Magnetic Braking in trains, Electromagnetic damping, Induction furnace etc.In this process, there is a loss occur in this system to reduce this we need to increase the core resistance and there is more losses in eddy current where there is more frequency.

Advantages of eddy current:

- Eddy current process is more useful at the inspection process.

- This is a non-contact inspection process which does not affect the work.

- Inspection by this method is a fast and accurate process.

- We can inspect the coating layer which is applied to the different products.

- This is also used in a speedometer.

- This also used in an induction furnace process.

Disadvantages of eddy current:

- There is more leakage of flux occurred in it.

- Heat loss is more.

- This not useful to inspect all types of metals(Only conductive metals can be inspected)

- Complex designs are not inspected with accurately.